GFRP rebar glass fiber reinforced polymer bars are high-strength, light-weight composite materials using fiberglass (FK). They are termed as good for construction activity since they help in making the buildings strong, robust and make them last lifelong. In this feature, you guys are going to learn about the many beneficial aspects of installing glass fiber reinforced polymer bars in your construction projects and find out why they become mandatory when it comes to building strong structures.

Glass Fiber Reinforced Polymer bars by CQDJ are Lightweight. They are easy to move and place. These bars may be transported by workers relatively easily, and they are often installed without large machinery. It also means less steel is needed to build something, which can be a huge money-saver. These Fiberglass Rebar allow builders to reduce their overall costs, as well while making certain the buildings tend to be strong.

Another major plus is that the bars do not get rusty or erode over time. They are anti-corrosive, which differs them from the conventional materials. This is to ensure that water and chemicals which are harmful in general for building materials do not harm them. This durability element makes various building components to last longer, thus reducing the frequency and cost associated with repairs/replacements; which is great for long-term savings.

Secondly, these CQDJ bars do not rust and therefore increase the longevity of buildings. Steel materials and even supplies can end up corroded in time, which will move all the weaker system. FRP bars can be used in infrastructure and buildings where they will not rust, keeping them longer lasting stronger over the years. Waterproofing is crucial, this is particularly so in places that on an everyday basis face severe weather conditions.

Finally, these CQDJ bars are light weight so the building its self needs less support. They are thus made from less supporting materials of other kinds, potentially making the building even stronger. With less weight on the foundation, you are also reducing the risk of GRP Structural Shape sinking or settling which would create more problems down range. These measures are very important to safeguard the building and maintain structural integrity.

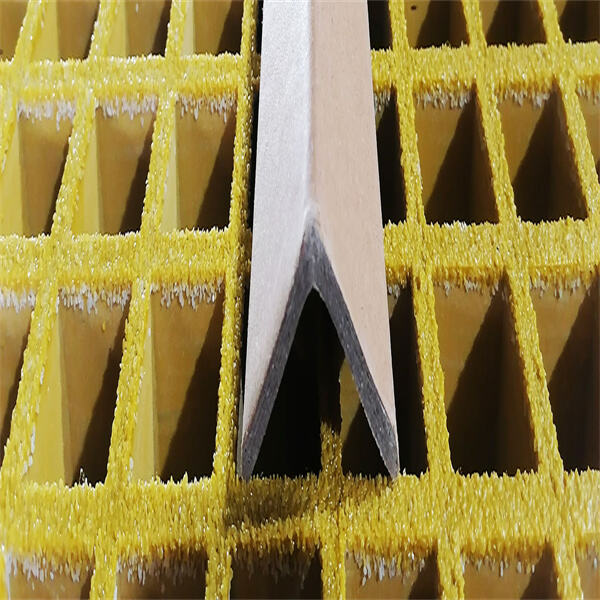

The materials that can be used to produce glass fiber reinforced polymer bars are varied. It is composed mainly of glass fibers formed by melting the processed material and pulling into fine strands. They bond these glass fibers together using a unique type of plastic resin, all so the boom is able to finally have its form and strength. That is the combination of materials that makes these bars such so powerful.

In addition, because glass-fiber-reinforced plastic pipes do not rust, their life cycle is longer than traditional materials. Replacement and maintenance fees will be lower too, which could save you thousands of dollars over time. Utilizing such Fiberglass Tube prevents any possibility for rust and decay, products that typically accompany the use of traditional materials at extremely high costs.

One of the main selling features of our fiberglass products is their value Despite their excellent performance they are also cost-effective and provide great value for money Our wide range of sizes and customizable options allow our clients to find the ideal Glass fiber reinforced polymer bars to their requirements If it's a standard fiberglass profile or customized fiberglass rebar we have the ability to meet a variety of requirements In all we are able to make a variety of different fiberglass profiles including rods tubes and custom shapes

The fiberglass we use is renowned for being extremely durable as well as durable and versatile. Our Glass fiber reinforced polymer bars are made with the most advanced techniques and quality materials. Our products, be it the fiberglass rod used to construct or a fiberglass tube used in industrial applications, are made to last. Our products are light and durable, making them ideal for a variety of applications.

We're committed to continual research and development to enhance our products. Our clients are actively informed and we continue to invest in improvement to keep our products top of the line in their field. The after-sales assistance as well as our technical expertise is unbeatable giving our customers peace of mind and trust in the quality of our fiberglass products. The profiles we offer are sold Glass fiber reinforced polymer bars to Southeast Asia, the Middle East and North America, a total of 60 countries.

Our company stands out in the industry for our commitment to quality and innovation With 40 years of experience in the manufacture of fiberglass rods profile profiles tubes rebars and Glass fiber reinforced polymer bars we have established ourselves as a reliable dependable supplier Our commitment to customer satisfaction and continual advancement sets us apart from the rest of the market Transparency transparency and open communication are essential for us We want our clients to be informed and actively engaged

Copyright © Chongqing Dujiang Composites Co., Ltd. All Rights Reserved