Fiberglass reinforced rebar suppliers for concrete

- Overview

- Recommended Products

PROPERTY

The properties of fiberglass rebar include:

Strength: Fiberglass rebar has high tensile strength, allowing it to effectively reinforce concrete structures.

Corrosion resistance: Unlike steel rebar, fiberglass rebar does not rust or corrode, making it ideal for use in environments with high moisture or chemical exposure.

Lightweight: Fiberglass rebar is significantly lighter than steel rebar, which can ease transportation, handling, and installation.

Non-conductive: Fiberglass rebar does not conduct electricity, which can be advantageous in certain construction applications.

Thermal insulation: Fiberglass rebar has low thermal conductivity, providing some insulating properties in comparison to metal rebar.

These properties make fiberglass rebar a popular choice for reinforcing concrete structures in various construction projects.

APPLICATION

Fiberglass rebar is commonly used in a wide range of construction applications where traditional steel rebar may not be ideal. Some common applications of fiberglass rebar include:

1.Marine structures: Fiberglass rebar is often used in seawalls, piers, docks, and other marine structures due to its resistance to corrosion in saltwater environments.

2.Bridges and highways: Fiberglass rebar is used to reinforce concrete in bridge decks, highway pavements, and other transportation infrastructure where corrosion resistance is important.

3.Industrial facilities: Fiberglass rebar is employed in the construction of industrial facilities, such as chemical plants and wastewater treatment plants, where exposure to corrosive chemicals and moisture is a concern.

4.Parking structures: The use of fiberglass rebar in parking garages and other concrete structures can help prevent corrosion from de-icing salts and other chemicals.

5.Residential construction: Fiberglass rebar is also increasingly being used in residential construction for applications such as foundations, slabs, and retaining walls where corrosion resistance and lightweight properties are advantageous.

Overall, fiberglass rebar is well-suited for any concrete reinforcement application where corrosion resistance, lightweight properties, and non-conductive features are valued.

TECHNICAL INDEXS

| Diameter (mm) | Cross Section (mm2) | Density (g/cm3) | Weight (g/m) | Ultimate Tensile Strength (MPa) | Elastic Modulus (GPa) |

| 3 | 7 | 2.2 | 18 | 1900 | >40 |

| 4 | 12 | 2.2 | 32 | 1500 | >40 |

| 6 | 28 | 2.2 | 51 | 1280 | >40 |

| 8 | 50 | 2.2 | 98 | 1080 | >40 |

| 10 | 73 | 2.2 | 150 | 980 | >40 |

| 12 | 103 | 2.1 | 210 | 870 | >40 |

| 14 | 134 | 2.1 | 275 | 764 | >40 |

| 16 | 180 | 2.1 | 388 | 752 | >40 |

| 18 | 248 | 2.1 | 485 | 744 | >40 |

| 20 | 278 | 2.1 | 570 | 716 | >40 |

| 22 | 355 | 2.1 | 700 | 695 | >40 |

| 25 | 478 | 2.1 | 970 | 675 | >40 |

| 28 | 590 | 2.1 | 1195 | 702 | >40 |

| 30 | 671 | 2.1 | 1350 | 637 | >40 |

| 32 | 740 | 2.1 | 1520 | 626 | >40 |

| 34 | 857 | 2.1 | 1800 | 595 | >40 |

| 36 | 961 | 2.1 | 2044 | 575 | >40 |

| 40 | 1190 | 2.1 | 2380 | 509 | >40 |

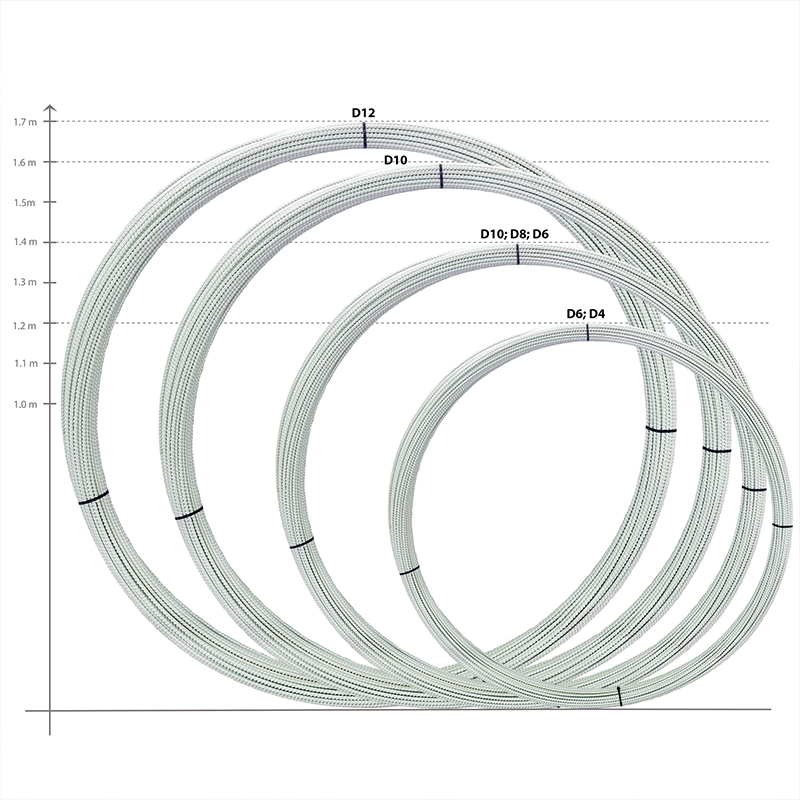

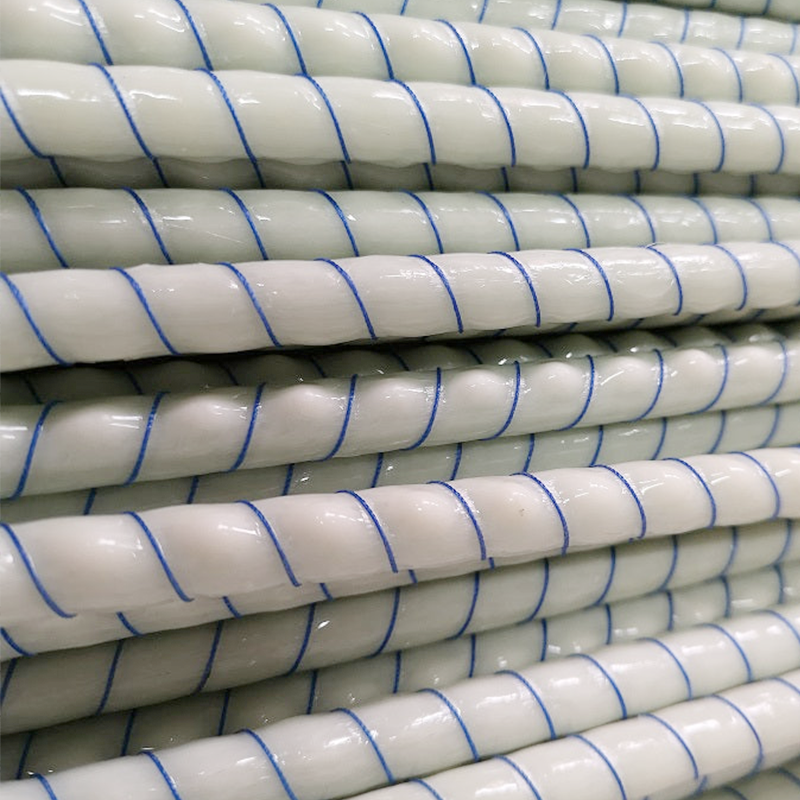

PACKING AND STORAGE

The packages of fiberglass rebar typically consist of bundles of rebar that are securely tied together with strapping or placed in cardboard boxes to prevent shifting or damage during transportation. The specific packaging may vary depending on the manufacturer and the distributor. If you need more detailed information on the packaging of fiberglass rebar, I recommend reaching out to our company for precise details.