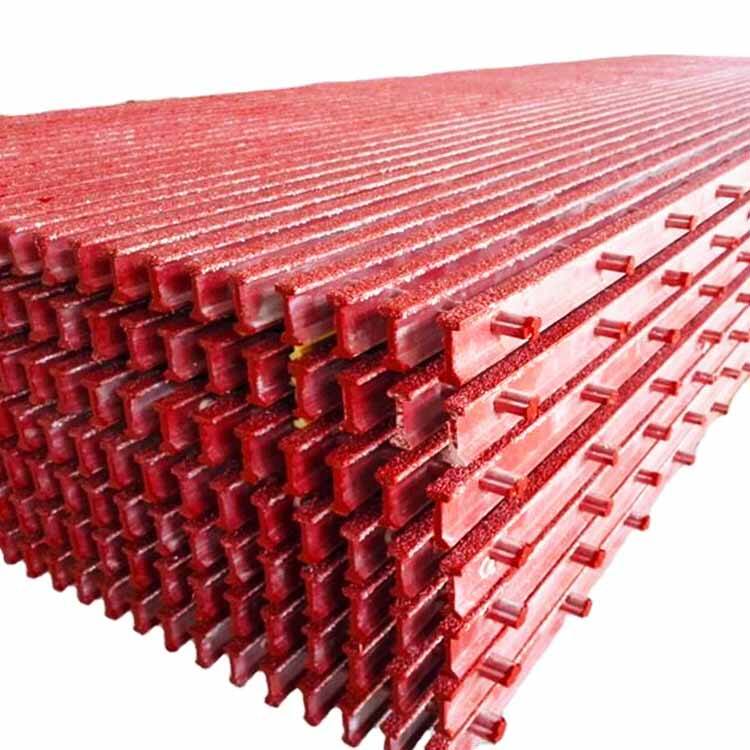

Fiberglass Pultruded Grating for Walkways and Platforms

- Overview

- Recommended Products

Product Feature

Fiberglass pultruded grating offers several key features, including:

Corrosion Resistance: Fiberglass grating is highly resistant to corrosion, making it suitable for harsh environments such as chemical plants, wastewater treatment facilities, and marine applications.

High Strength-to-Weight Ratio: It provides high strength while remaining lightweight, which makes it easier to handle and install compared to traditional metal gratings.

Low Maintenance: Fiberglass pultruded grating requires minimal maintenance, reducing long-term costs and labor associated with upkeep.

Non-Conductive: It is non-conductive and non-magnetic, making it a safe choice for electrical and magnetic-sensitive environments.

Fire Retardant: Many fiberglass gratings are manufactured with flame-retardant resin, adding an extra level of safety in case of fire.

UV Resistant: The material is UV resistant, making it suitable for outdoor applications without degradation from sunlight exposure.

Slip Resistance: The surface of the grating is designed to provide slip resistance, enhancing safety for pedestrians and workers.

Overall, fiberglass pultruded grating is a versatile and durable option for various industrial, commercial, and residential applications.

Product Category

Type HL

X: Opening mesh size

Y:BEARING BAR THICKNESS(TOP/BOTTOM)

Z: Center to Center of the distance of the Bearing bar

| TYPE | HIGHT(MM) | X(MM) | Y(MM) | Z(MM) | STANDARD PANEL SIZE AVAILABLE(MM) | APPROX. WEIGHT(KG/M²) | OPEN RATE(%) | #BARS/FT | LOAD DEFLECTION TABLE |

| HL-4020 | 50 | 10 | 15 | 25 | 1220mm,915mm-wide3050mm,6100mm-long | 70.1 | 40% | 12 | |

| HL-50204720 | 50 | 15 | 15 | 30 | 1220mm,915mm-wide3050mm,6100mm-long | 52.0 | 50% | 10 | AVAILABLE |

| HL-60205820 | 50 | 23 | 15 | 38 | 1220mm,915mm-wide3050mm,6100mm-long | 44.0 | 60% | 8 | AVAILABLE |

| HL-6520 | 50 | 28 | 15 | 43 | 1220mm,915mm-wide3050mm,6100mm-long | 33.5 | 65% | 7 | |

| HL-5825 | 64 | 22 | 16 | 38 | 1220mm,915mm-wide3050mm,6100mm-long | 48.0 | 58% | 8 | AVAILABLE |

Product Application

Fiberglass pultruded grating has a wide range of applications across various industries due to its beneficial characteristics. Some common applications include:

Industrial Platforms and Walkways: Fiberglass pultruded grating is often used to create robust and slip-resistant walkways and platforms in industrial facilities, providing a safe and durable walking surface for workers.

Chemical Processing Plants: The corrosion-resistant nature of fiberglass pultruded grating makes it an ideal choice for use in chemical processing plants where exposure to corrosive chemicals is a concern.

Water and Wastewater Treatment Facilities: The non-corrosive and non-conductive properties of fiberglass pultruded grating make it suitable for use in water and wastewater treatment facilities where exposure to moisture and chemicals is common.

Offshore and Marine Applications: Due to its resistance to saltwater corrosion, fiberglass pultruded grating is used in offshore platforms, ship decks, and other marine applications.

Food and Beverage Processing: Fiberglass pultruded grating is commonly employed in food and beverage processing facilities due to its resistance to corrosion and ease of cleaning.

Cooling Towers and Chemical Storage Areas: Its resistance to both chemical corrosion and high temperatures makes fiberglass pultruded grating suitable for use in cooling towers and chemical storage areas.

Architectural and Construction Projects: Fiberglass pultruded grating can be used in architectural and construction projects for elements such as catwalks, stair treads, and sunscreens due to its strength, versatility, and low maintenance requirements.

These are just a few examples of the many applications of fiberglass pultruded grating across a variety of industries. Its versatility, durability, and resistance to corrosion make it a popular choice for demanding environments.