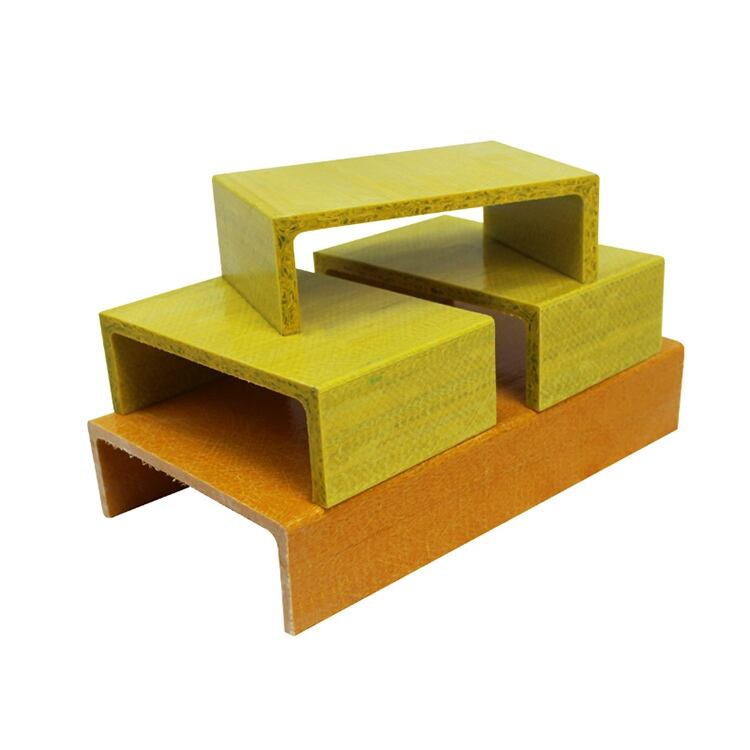

Fiberglass c channel manufacturers

- Overview

- Recommended Products

Technical indexs

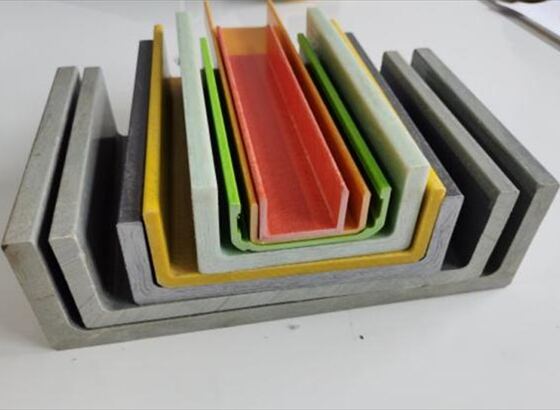

| Type | Dimension(mm)AxBxT | Weight(Kg/m) |

| 1-C50 | 50x14x3.2 | 0.44 |

| 2-C50 | 50x30x5.0 | 1.06 |

| 3-C60 | 60x50x5.0 | 1.48 |

| 4-C76 | 76x35x5 | 1.32 |

| 5-C76 | 76x38x6.35 | 1.70 |

| 6-C89 | 88.9x38.1x4.76 | 1.41 |

| 7-C90 | 90x35x5 | 1.43 |

| 8-C102 | 102x35x6.4 | 2.01 |

| 9-C102 | 102x29x4.8 | 1.37 |

| 10-C102 | 102x29x6.4 | 1.78 |

| 11-C102 | 102x35x4.8 | 1.48 |

| 12-C102 | 102x44x6.4 | 2.10 |

| 13-C102 | 102x35x6.35 | 1.92 |

| 14-C120 | 120x25x5.0 | 1.52 |

| 15-C120 | 120x35x5.0 | 1.62 |

| 16-C120 | 120x40x5.0 | 1.81 |

| 17-C127 | 127x35x6.35 | 2.34 |

| 18-C140 | 139.7x38.1x6.4 | 2.45 |

| 19-C150 | 150x41x8.0 | 3.28 |

| 20-C152 | 152x42x6.4 | 2.72 |

| 21-C152 | 152x42x8.0 | 3.35 |

| 22-C152 | 152x42x9.5 | 3.95 |

| 23-C152 | 152x50x8.0 | 3.59 |

| 24-C180 | 180x65x5 | 2.76 |

| 25-C203 | 203x56x6.4 | 3.68 |

| 26-C203 | 203x56x9.5 | 5.34 |

| 27-C254 | 254x70x12.7 | 8.90 |

| 28-C305 | 305x76.2x12.7 | 10.44 |

Advantages

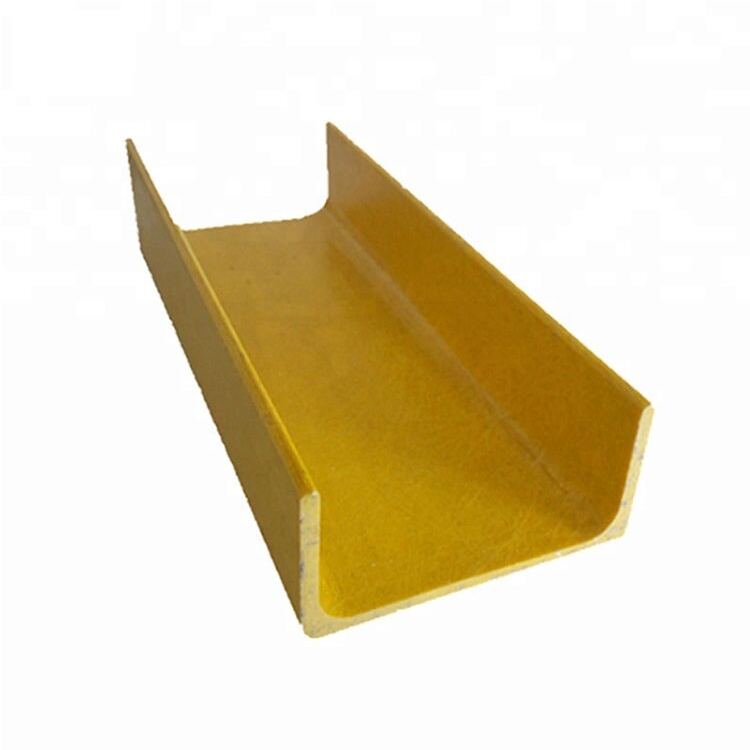

1.Fiberglass C channels offer several advantages, including:High strength-to-weight ratio: Fiberglass C channels are lightweight yet strong, providing excellent structural support without adding significant weight to the overall structure.

2.Corrosion resistance:Fiberglass does not rust or corrode, making it ideal for use in harsh environments, such as those with high moisture, chemical exposure, or saltwater.

3.Non-conductivity:Fiberglass is non-conductive, making it suitable for use in electrical and electronic applications where metal components may pose a risk of electrical conductivity.

4.Low maintenance:Fiberglass C channels require minimal maintenance and have a long service life, reducing the need for frequent repairs or replacements.

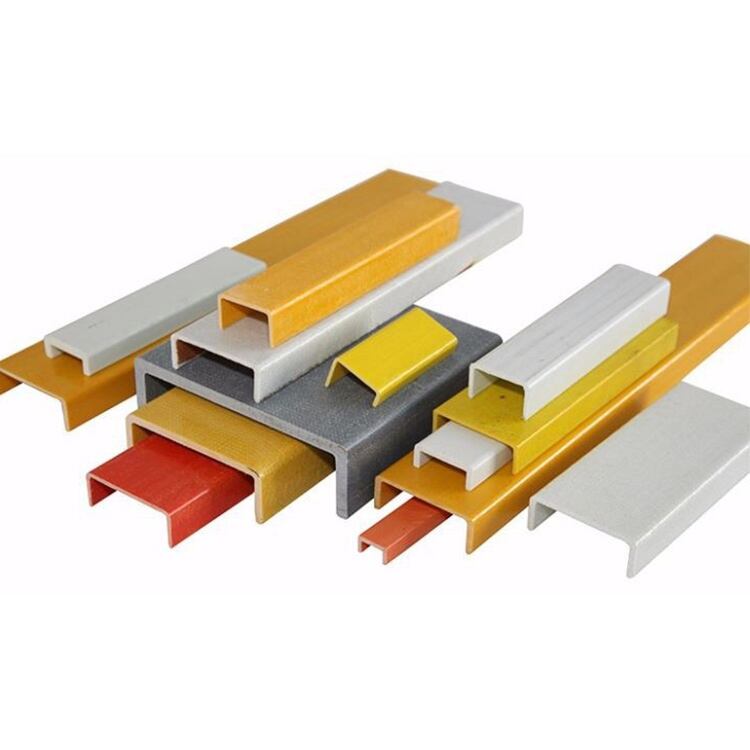

5.Design flexibility:Fiberglass C channels can be easily customized and designed to meet specific requirements, including varying lengths, colors, and load-bearing capacities.

6.Environmental resistance:Fiberglass is resistant to UV exposure, extreme temperatures, and environmental degradation, making it suitable for outdoor and harsh climate applications.

Overall, fiberglass C channels offer a durable, cost-effective, and versatile solution for a wide range of structural and support applications.

Applications

Fiberglass C channels have a wide range of applications across various industries, thanks to their versatile properties. Some common applications include:

1.Building and construction:Fiberglass C channels are used as structural supports, framing components, and reinforcements in buildings, bridges, and other construction projects. Their high strength-to-weight ratio makes them ideal for these applications.

2.Electrical and utility:Fiberglass C channels are used in the electrical and utility sectors for cable management, equipment supports, and as non-conductive structural components, suitable for use in substations and power distribution facilities.

3.Marine and offshore:Due to their corrosion resistance, fiberglass C channels are used in marine and offshore applications for building boat structures, docks, platforms, and other marine infrastructure where exposure to saltwater and harsh environmental conditions is a concern.

4.Chemical processing:In chemical plants and industrial facilities, fiberglass C channels are utilized for supporting chemical processing equipment, walkways, and platforms, as they offer exceptional resistance to corrosion and chemical exposure.

5.Transportation:Fiberglass C channels find applications in the transportation industry for the construction of lightweight and durable components, such as truck bodies, vehicle ramps, and structural supports.

6.Renewable energy:Fiberglass C channels are used in the renewable energy sector for creating structural supports for solar panel arrays, wind turbine platforms, and other related infrastructure due to their strength, durability, and resistance to environmental elements.

These applications are just a few examples of where fiberglass C channels are utilized, demonstrating their versatility and suitability for a wide range of industries and projects.