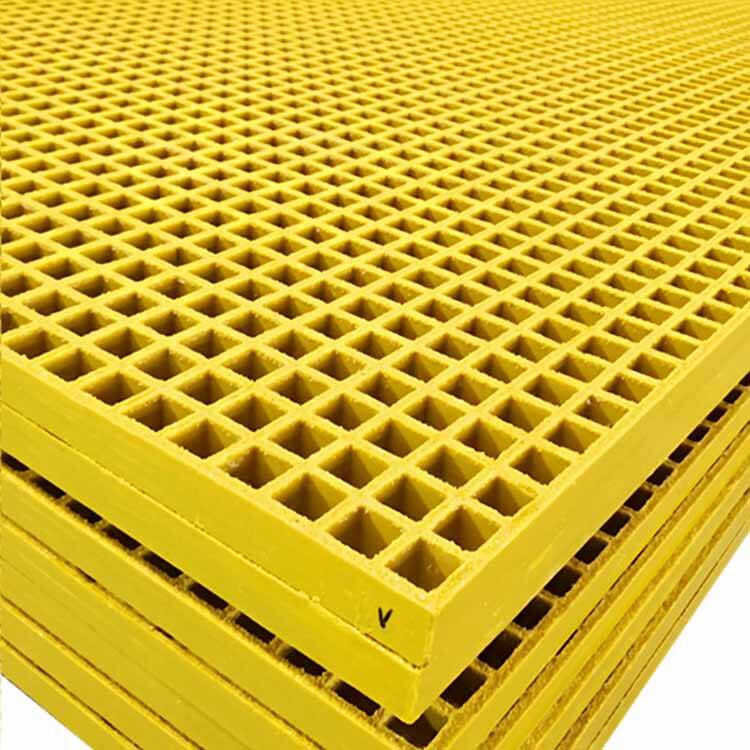

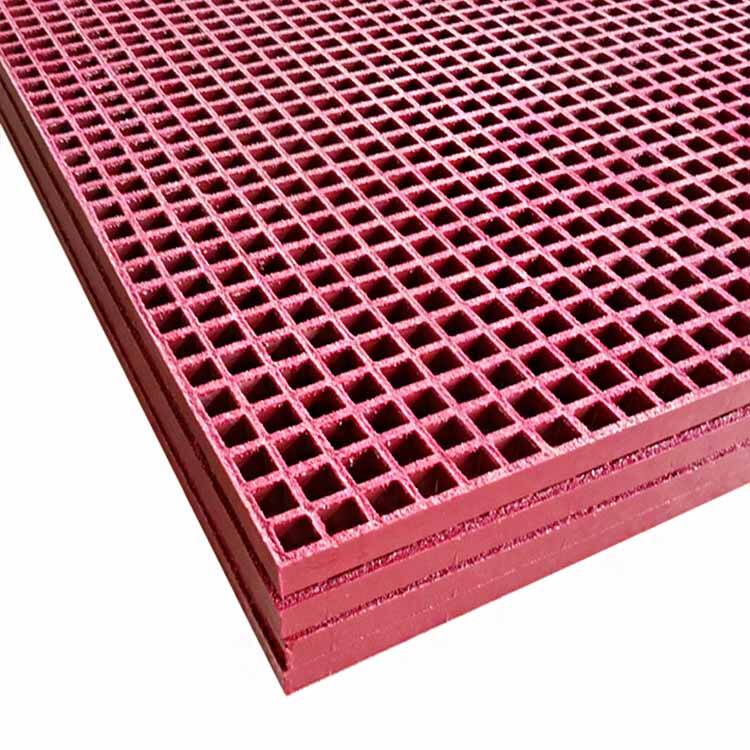

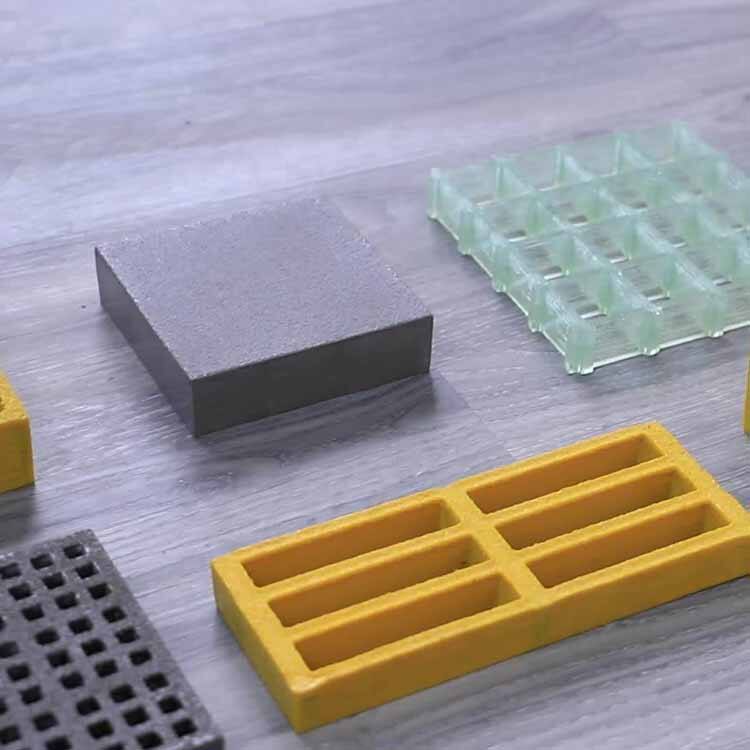

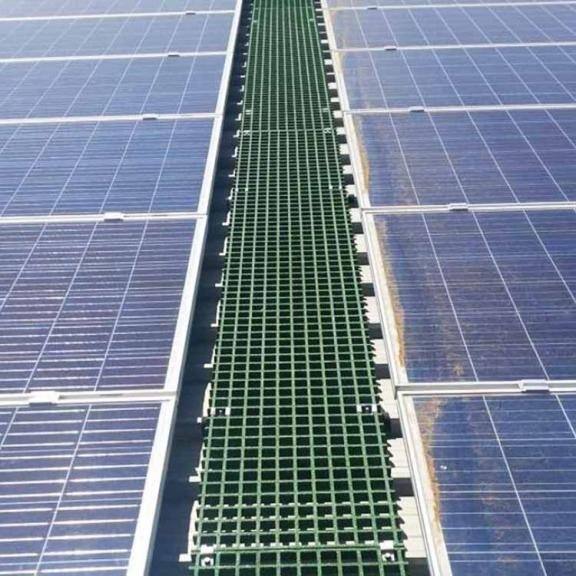

Fiberglass Molded Grating Customizable Solutions

- Overview

- Recommended Products

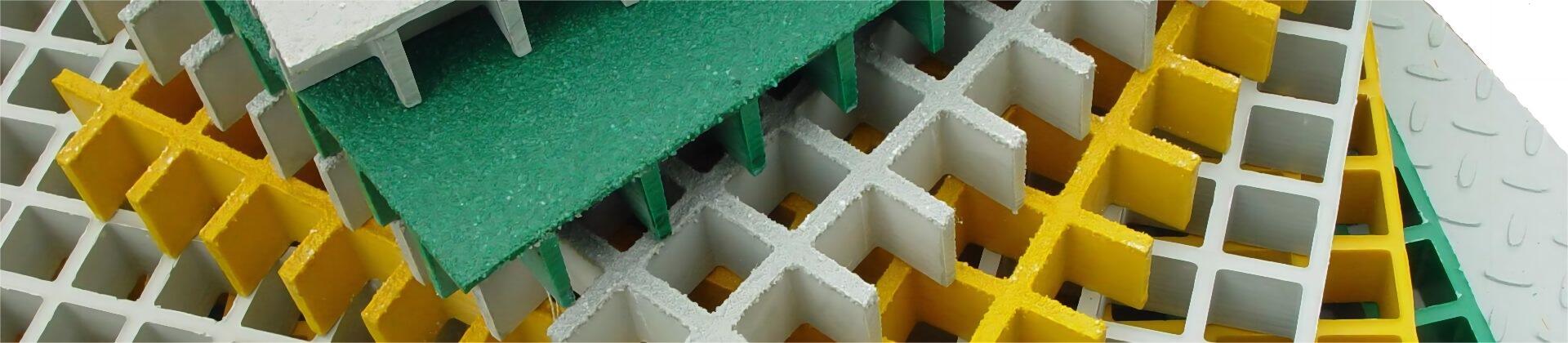

Structure Of CQDJ Molded Gratings

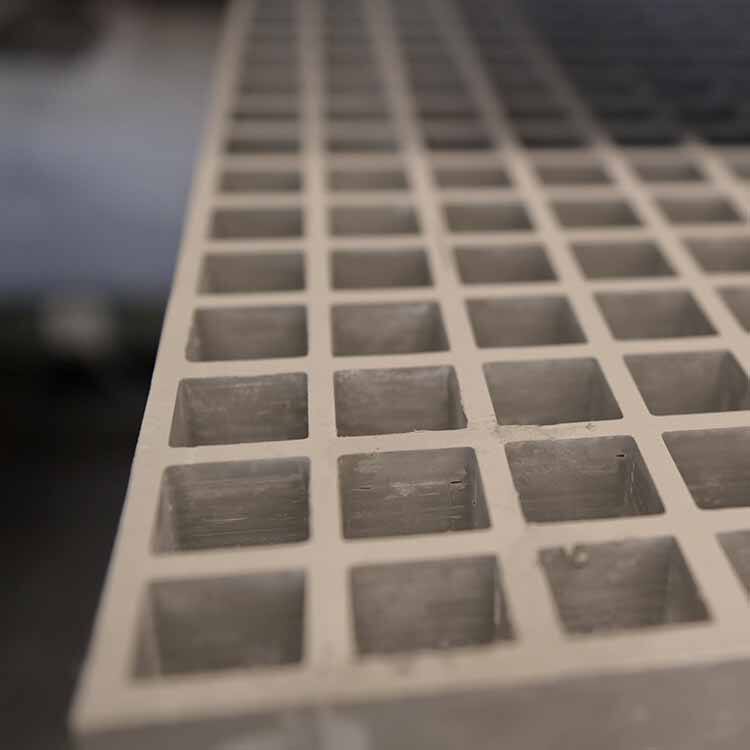

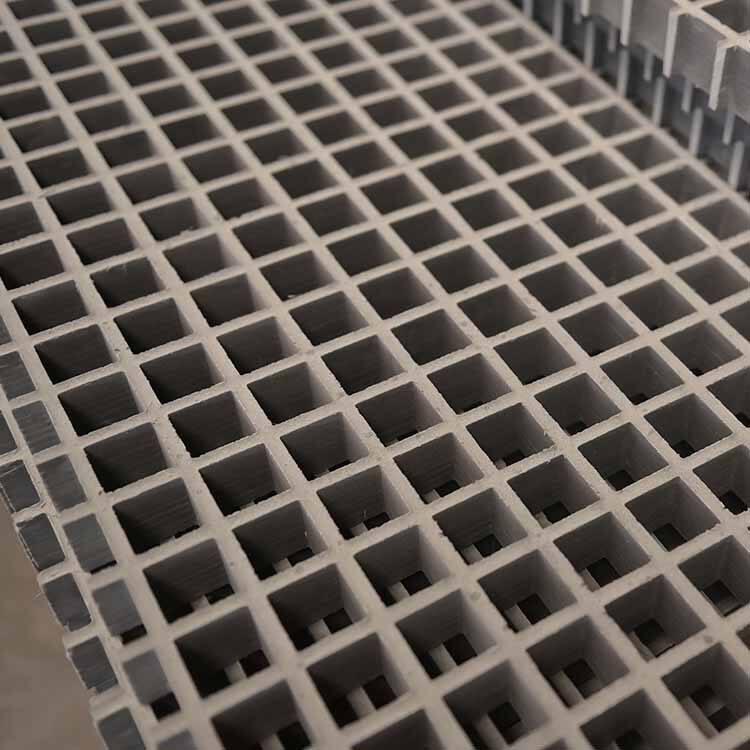

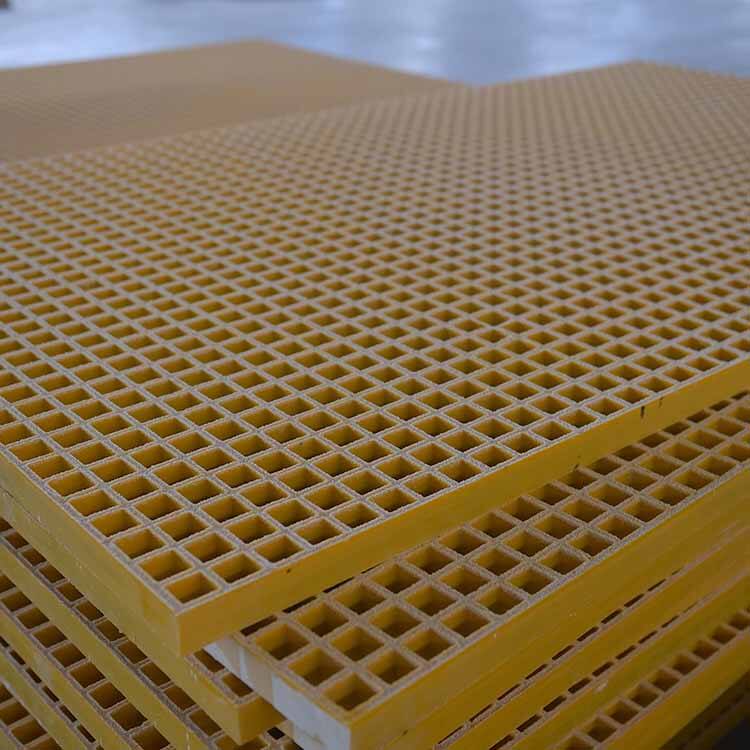

CQDJ Molded Gratings are created by weaving fiberglass roving and curing it in a single mold.

1. The resin is fully impregnated with an interwoven structure, providing excellent corrosion resistance.

2. overall design helps distribute loads evenly and enhances the installation and mechanical properties of the supporting structure.

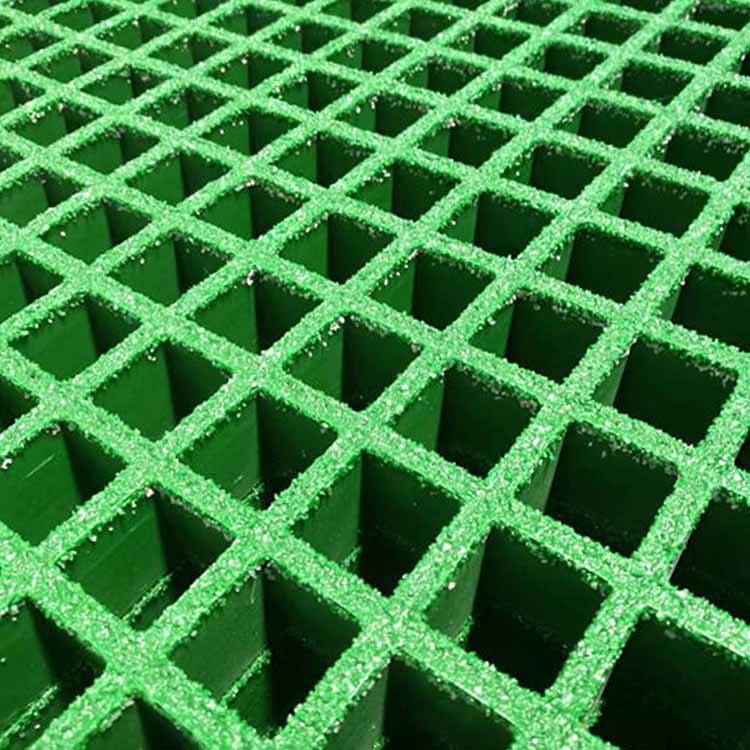

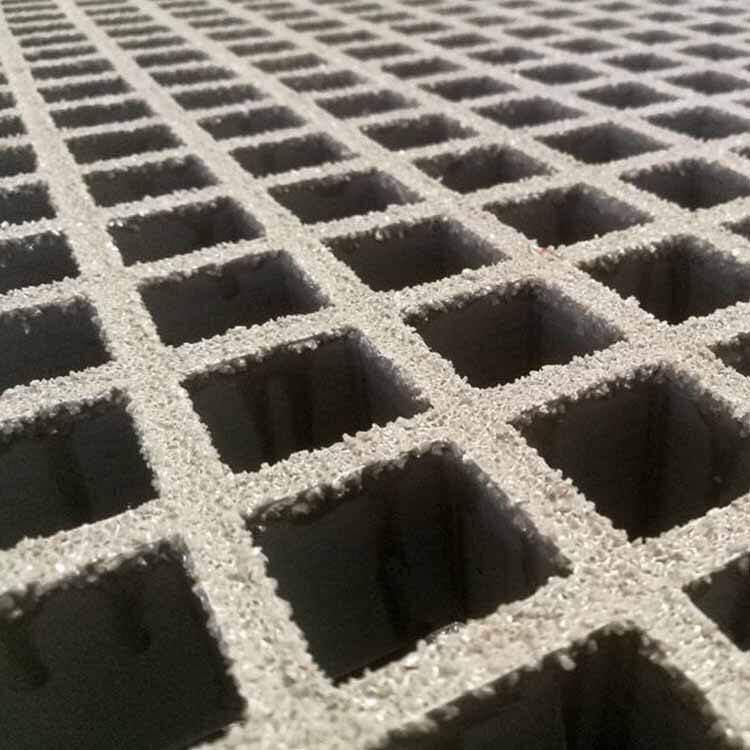

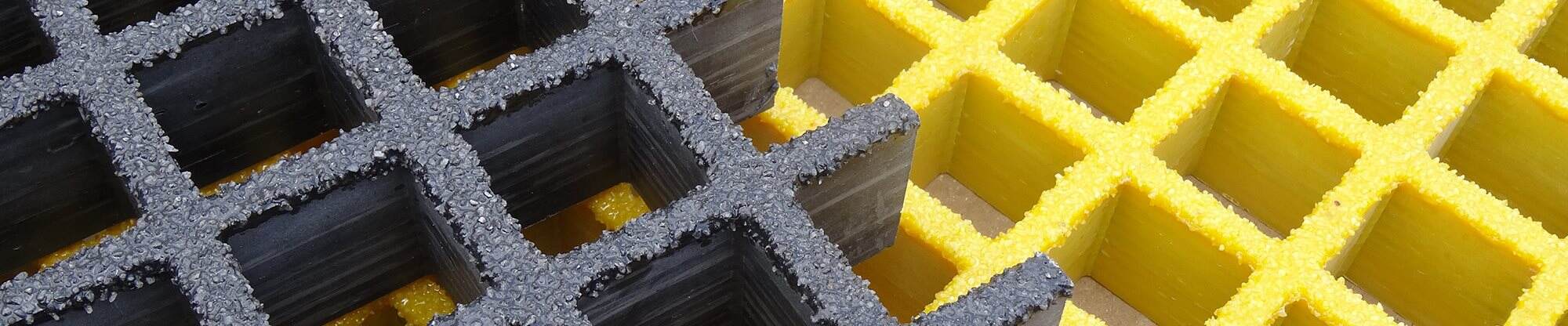

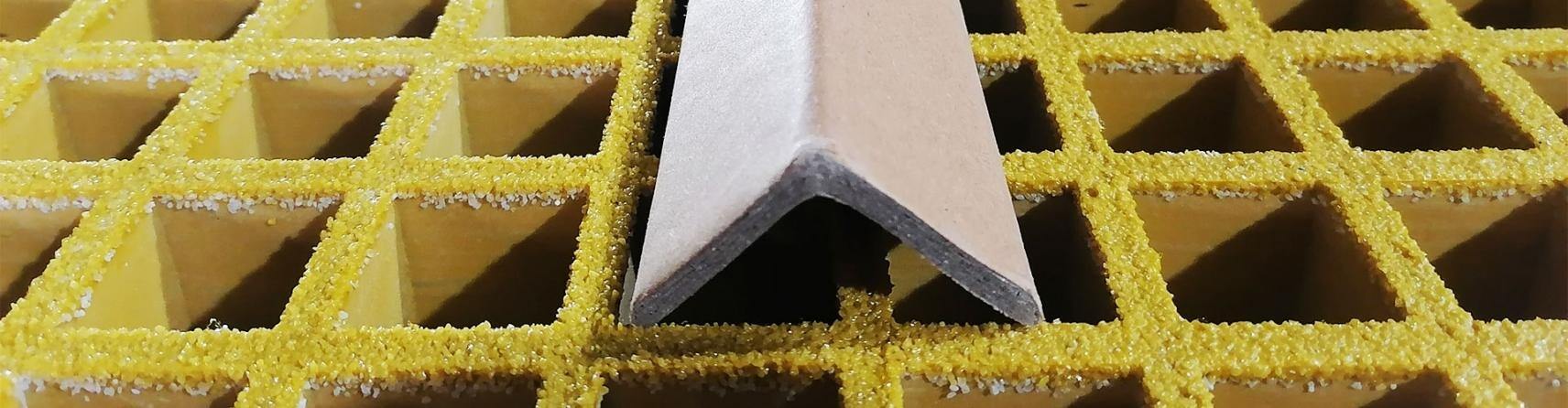

3. The grating's smooth and sliding surfaces offer self-cleaning advantages, while the concave surface ensures effective anti-slip functionality.

4. Additionally, the gritted surface enhances slip resistance even further.

Properties Of CQDJ Molded Gratings

Fiberglass molded gratings have several properties that make them suitable for various applications. Some key properties of fiberglass molded gratings include:

1.Corrosion resistance:Fiberglass molded gratings are highly resistant to corrosion, making them ideal for use in harsh and corrosive environments such as chemical plants, marine facilities, and wastewater treatment plants.

2.High strength-to-weight ratio:These gratings are lightweight yet strong, providing a durable and long-lasting solution for structural support and access platforms.

3.Non-conductivity:Fiberglass gratings are non-conductive, making them suitable for use in electrical and telecommunications applications where electrical insulation is required.

4.Impact resistance:The durable nature of fiberglass makes molded gratings resistant to impact and able to withstand heavy loads without deforming or breaking.

5.Slip resistance:The surface of fiberglass molded gratings can be designed to provide slip resistance, enhancing safety in areas where moisture or oils may be present.

6.UV resistance:Fiberglass gratings are resistant to UV degradation, making them suitable for outdoor applications where exposure to sunlight is a concern.

7.Easy installation and maintenance:Fiberglass molded gratings are easy to install and require minimal maintenance, reducing overall operational costs.

These properties make fiberglass molded gratings a versatile and cost-effective solution for a wide range of industrial, commercial, and residential applications.

Products

1. MESH SIZE:38.1x38.1MM(40x40mm/50x50mm/83x83mm and so on)

| HIGHT(MM) | BEARING BAR THICKNESS (TOP/BOTTOM) | MESH SIZE (MM) | STANDARD PANEL SIZE AVAILABLE (MM) | APPROX. WEIGHT(KG/M²) | OPEN RATE(%) | LOAD DEFLECTION TABLE |

| 13 | 6.0/5.0 | 38.1x38.1 | 1220x4000 | 6.0 | 68% | |

| 1220x3660 | ||||||

| 15 | 6.1/5.0 | 38.1x38.1 | 1220x4000 | 7.0 | 65% | |

| 20 | 6.2/5.0 | 38.1x38.1 | 1220x4000 | 9.8 | 65% | AVAILABLE |

| 25 | 6.4x5.0 | 38.1x38.1 | 1524x4000 | 12.3 | 68% | AVAILABLE |

| 1220x4000 | ||||||

| 1220x3660 | ||||||

| 998x4085 | ||||||

| 30 | 6.5/5.0 | 38.1x38.1 | 1524x4000 | 14.6 | 68% | AVAILABLE |

| 996x4090 | ||||||

| 996x4007 | ||||||

| 1220x3660 | ||||||

| 1220x4312 | ||||||

| 35 | 10.5/9.0HEAVY DUTY | 38.1x38.1 | 1227x3666 | 29.4 | 56% | |

| 1226x3667 | ||||||

| 38 | 7.0/5.0 | 38.1x38.1 | 1524x4000 | 19.5 | 68% | AVAILABLE |

| 1220x4235 | ||||||

| 1220x4000 | ||||||

| 1220x3660 | ||||||

| 1000x4007 | ||||||

| 1226x4007 | ||||||

| 50 | 11.0/9.0HEAVY DUTY | 38.1x38.1 | 1220x4225 | 42.0 | 56% | |

| 60 | 11.5/9.0HEAVY DUTY | 38.1x38.1 | 1230x4000 | 50.4 | 56% | |

| 1230x3666 |

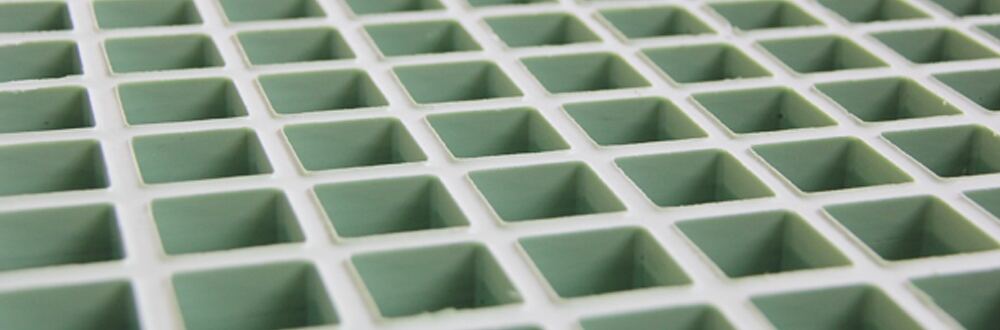

2.MICRO MESH SIZE:13x13/40x40MM(we can provide oem and odm)

| HIGHT(MM) | BEARING BAR THICKNESS (TOP/BOTTOM) | MESH SIZE (MM) | STANDARD PANEL SIZE AVAILABLE (MM) | APPROX. WEIGHT(KG/M²) | OPEN RATE (%) | LOAD DEFLECTION TABLE |

| 22 | 6.4&4.5/5.0 | 13x13/40x40 | 1527x4047 | 14.3 | 30% | |

| 25 | 6.5&4.5/5.0 | 13x13/40x40 | 1247x4047 | 15.2 | 30% | |

| 30 | 7.0&4.5/5.0 | 13x13/40x40 | 1527x4047 | 19.6 | 30% | |

| 38 | 7.0&4.5/5.0 | 13x13/40x40 | 1527x4047 | 20.3 | 30% |

3. MINI MESH SIZE:19x19/38x38MM(we can provide oem and odm)

| HIGHT(MM) | BEARING BAR THICKNESS (TOP/BOTTOM) | MESH SIZE (MM) | STANDARD PANEL SIZE AVAILABLE (MM) | APPROX. WEIGHT(KG/M²) | OPEN RATE (%) | LOAD DEFLECTION TABLE |

| 25 | 6.4/5.0 | 19.05x19.05/38.1x38.1 | 1220x4000 | 16.8 | 40% | |

| 30 | 6.5/5.0 | 19.05x19.05/38.1x38.1 | 1220x3660 | 17.5 | 40% | |

| 38 | 7.0/5.0 | 19.05x19.05/38.1x38.1 | 1220x4000 | 23.5 | 40% | |

| 1524x4000 |

4. 25mm DeepX25mmX102mm Rectangular

| PANEL SIZES(MM) | #OF BARS/M OF WIDTH | LOAD BAR WIDTH | THE BAR WIDTH | OPEN AREA | LOAD BAR CENTERS | APPROX WEIGHT | |

| Design(A) | 3048*914 | 39 | 9.5mm | 6.4mm | 69% | 25mm | 12.2kg/m² |

| 2438*1219 | |||||||

| Design(B) | 3658*1219 | 39 | 13mm | 6.4mm | 65% | 25mm | 12.7kg/m² |

5. 25mm DeepX38mm square mesh

| #OF BARS/M OF WIDTH | LOAD BAR WIDTH | OPEN AREA | LOAD BAR CENTERS | APPROX WEIGHT |

| 26 | 6.4mm | 70% | 38mm | 12.2kg/m² |

Applications

Fiberglass molded grating has a wide range of applications in various industries and settings due to its versatility and beneficial properties. Some common applications of fiberglass molded grating include:

1.Industrial platforms and walkways:Fiberglass grating is often used to construct access platforms, walkways, and catwalks in industrial facilities, providing a durable and slip-resistant surface for worker safety.

2.Marine and offshore installations:The corrosion resistance and durability of fiberglass molded grating make it suitable for use in marine environments, such as offshore platforms, docks, piers, and marinas.

3.Chemical processing plants:Fiberglass grating is used in chemical facilities due to its excellent resistance to corrosion from harsh chemicals, acids, and alkalis.

4.Water and wastewater treatment plants:The non-corrosive nature and high strength-to-weight ratio of fiberglass grating make it an ideal material for use in water treatment facilities where exposure to moisture and chemicals is common.

5.Oil and gas industry:Fiberglass grating is utilized in oil and gas refineries, offshore rigs, and processing facilities due to its resistance to corrosion, non-conductivity, and ability to withstand heavy loads.

6.Food processing and beverage industry:Fiberglass grating is often used in food and beverage processing plants and breweries due to its resistance to corrosion, ease of cleaning, and compliance with hygiene requirements.

7.Commercial and public facilities:Fiberglass grating can be found in commercial buildings, public spaces, and transportation hubs as a durable and safe flooring solution for pedestrian walkways, mezzanines, and stair treads.

These are just a few examples of the many applications of fiberglass molded grating, demonstrating its wide-ranging utility across various industries and environments.

Packages

1.Cardboard, foam, or other protective materials to prevent damage

2.It's best to discuss this with the supplier or manufacturer when placing your order.