The Future of Fiberglass Rods: A Look into the Production Process and Advantages

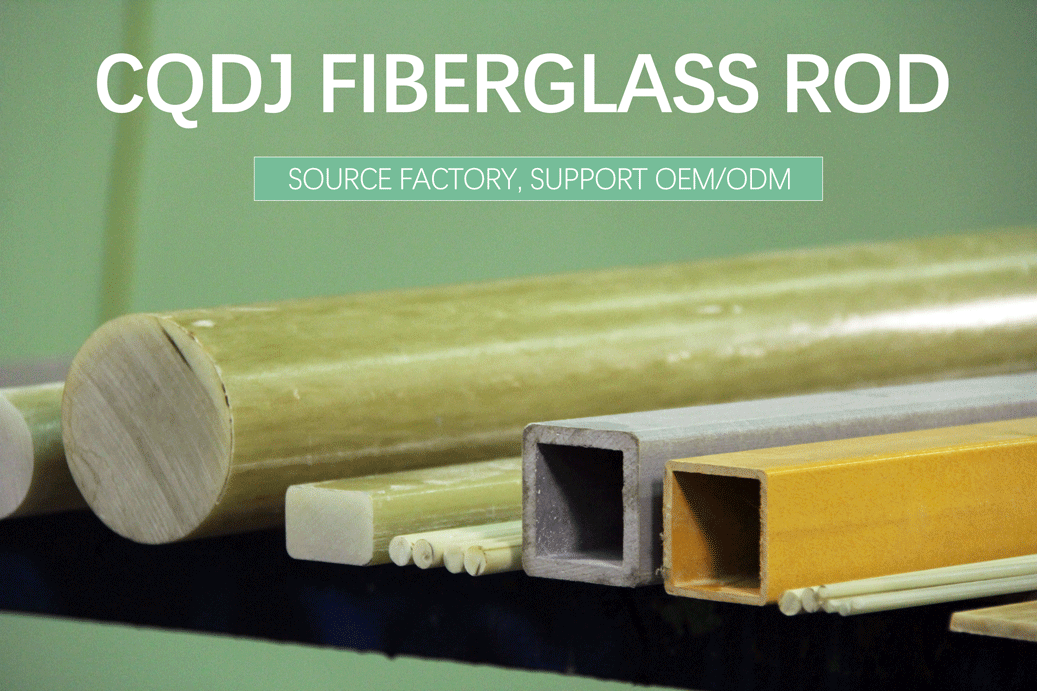

Fiberglass rods are tubular FRP products processed using fiberglass and thermosetting resin. They are recognized for their special properties and are increasingly used in various applications across industries such as offshore and onshore, entertainment, food, public facilities, power plants, agriculture, and more. In this article, we will delve into our company's production process, raw materials, advantages, daily production capacity, customization services, and warehouse storage of fiberglass rods.

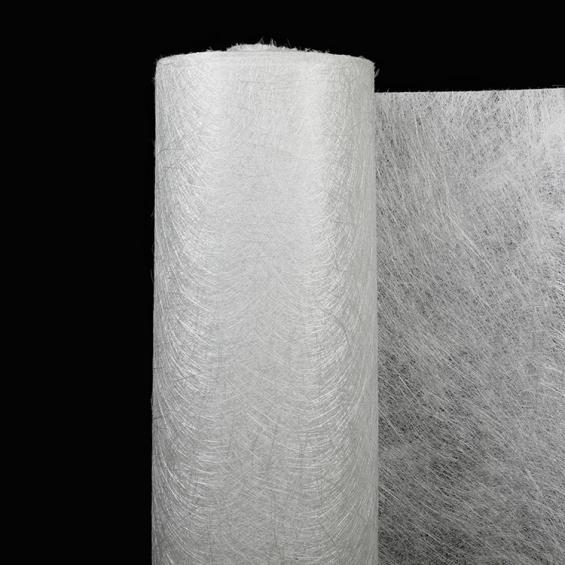

Raw Materials: The raw materials used in the production of fiberglass rods include fiberglass roving, fiberglass mat, and thermosetting resin. The glass fiber tubes are made of various raw materials such as polyester resin, anti-corrosion vinyl ester resin, epoxy resin, phenolic, and polyurethane. These different raw materials provide varying physical, mechanical, and chemical properties to the fiberglass tubes, allowing for customization based on specific use environments and requirements.

Advantages: Fiberglass rods offer several advantages, making them a preferred choice in various industries. They are corrosion, weather, humidity, and insect resistant, making them suitable for diverse environments. Additionally, they are easy to drill, cut, and install, and are more impact-resistant than wood. Fiberglass rods also exhibit high tensile strength and are stronger than steel in certain applications, especially as reinforcement material.

Daily Production Capacity: Our production facility can manufacture a substantial number of fiberglass rods daily, catering to the growing demand across different industries. The exact daily production capacity can be customized based on specific requirements and orders from clients. We currently have three production lines producing glass fiber rods. According to customer needs and order delivery time, we can add production lines to increase daily output.

Production Process: The production process of fiberglass rods involves the pultrusion process. This process is relatively simple, allowing for continuous production with a smooth surface finish. It offers high production efficiency and the ability to customize products according to customer needs. However, the production of large-sized products can be challenging, and the process requires high machine and process requirements.

Customization Services: We take pride in offering customized fiberglass rod products to meet the specific needs and requirements of our clients. Various cross-section fiberglass tubes can be customized according to customer specifications, ensuring that the products align with their intended applications.

Warehouse Storage: Our fiberglass rod warehouse is equipped to store and manage the inventory of our products efficiently. The warehouse is designed to ensure the safety and integrity of the fiberglass rods, allowing for organized storage and easy access to fulfill orders promptly.

In Conclusion: The future of fiberglass rods is promising, with their widespread application in industries such as construction, infrastructure, utilities, and more. The production process, raw materials, advantages, daily production capacity, customization services, and warehouse storage collectively contribute to the quality and reliability of our fiberglass rod products, meeting the diverse needs of our clients across various sectors.