Natuurlijk! Hieronder staat een gedetailleerdere beschrijving van de eigenschappen van glasvezelstaven:

(1)Hoge kracht-tot-gewicht verhouding

Glasvezelstaven worden gewaardeerd om hun lichte gewicht en sterke eigenschappen, met een relatieve dichtheid van ongeveer 1,9. Ze wegen slechts 1/4 tot 1/5 van koolstalen, maar hebben vergelijkbare of superieure treksterkte, waardoor ze ideaal zijn voor gewichtsgevoelige toepassingen zoals luchtvaart, raketten, ruimtevaartuigen en hoge-druk vaatsystemen. Bepaalde epoxy FRP varianten kunnen in verschillende tests krachten overtreffen van 400 MPa.

(2)Corrosiebestendigheid

FRP is hoog corrosiebestendig en kan blootstelling aan atmosferische omstandigheden, water, zuren, alkalien, zouten, olie en oplosmiddelen verdragen. Glasvezelstaven worden breed gebruikt voor chemische anticorrosie-toepassingen, waarmee traditionele materialen zoals koolstofstaal, roestvrij staal, hout en niet-ferrometalen worden vervangen.

(3)Flexibiliteit

Glasvezelstaven kunnen zo ontworpen worden dat ze flexibel zijn, wat ze geschikt maakt voor toepassingen waarbij een bepaald niveau van buigen of flexen vereist is zonder te breken.

(4)Elektrische isolatie

Glasvezelstaven hebben uitstekende isolatie-eigenschappen en sterke dielektrische kenmerken op hoge frequenties, en worden breed gebruikt in microwegoverdracht, zoals in radomen, wat betrouwbare elektrische isolatie en efficiënte signaaloverdracht garandeert in verschillende toepassingen.

(5)Thermische isolatie

FRP heeft een lage thermische geleidingsvatbaarheid van slechts 1.25 ~ 1.67 kJ/(m·h·K) bij kamertemperatuur, waardoor het een uitstekende keuze is voor toepassingen in thermische isolatie. Het biedt effectief thermische bescherming en weerstand tegen ablatie bij ultra-hoge temperaturen, waarbij ruimtevaartuigen worden beschermd tegen luchtstromen met snelheden die 2000°C overschrijden.

(6)Uitstekende productietechnieken

Het FRP-productieproces biedt flexibiliteit in productontwerp, technische specificaties en hoeveelheden. Het stelt eenmalig vormgeven toe, wat kosteneffectief is en voordelig voor de productie van complex gevormde producten of kleine series, wat de technologische superioriteit van FRP laat zien.

(7)Afmetingsstabielheid

Glasvezelstaven behouden hun vorm en afmetingen onder verschillende omgevingsomstandigheden, wat consistentie en betrouwbaarheid in prestaties garandeert.

(8)Radiofrequentietransparant

Glasvezelstaven kunnen transparant zijn voor radiofrequentie-golven, waardoor ze geschikt zijn voor toepassingen waarbij signaaloverdracht of ontvangst belangrijk is, zoals in elektronica of communicatieapparatuur.

Sollicitatie

Glasvezelstaven bieden uitzonderlijke presteer voordelen, wat leidt tot uitgebreide toepassingen in meer dan tien industrieën, zoals luchtvaart, spoorwegen, decoratieve architectuur, huishoudelijk meubilair, advertentiedisplays, kunstigefabrieken, bouwmateriaal, sanitair, jachthavens, sportmaterialen en milieubeheer. De veerkracht en prestaties van glasvezelstaven hebben hoge lof geoogst en ze erg gewild gemaakt in de moderne materialenindustrie.

Elektrisch en telecommunicatie: Glasvezelstaven worden gebruikt als structurele onderdelen in isolatoren, antennesuppo's en draadgidsen vanwege hun niet-geleidende eigenschappen en hoge sterkte.

Bouw en infrastructuur: Glasvezelstaven worden gebruikt in de bouw voor het versterken van beton, het maken van lichte structurele elementen en als onderdelen in bruggen en gebouwen.

Luchtvaart- en maritieme industrie: Glasvezelstaven worden gebruikt bij de constructie van vliegtuigen, boten en mariene structuren vanwege hun hoge kracht-gewichtsverhouding en corrosiebestendigheid.

Sportartikelen: Glasvezelstaven worden gebruikt bij de constructie van verschillende sportapparatuur zoals visroeden, boogschutter pijlen en tentpalen vanwege hun lage gewicht en flexibele eigenschappen.

Industriële toepassingen: Glasvezelstaven worden gebruikt in verschillende industriële toepassingen zoals gereedschaphandvaten, chemische verwerkingsapparatuur en machinedelen vanwege hun corrosiebestendigheid en hoge sterkte.

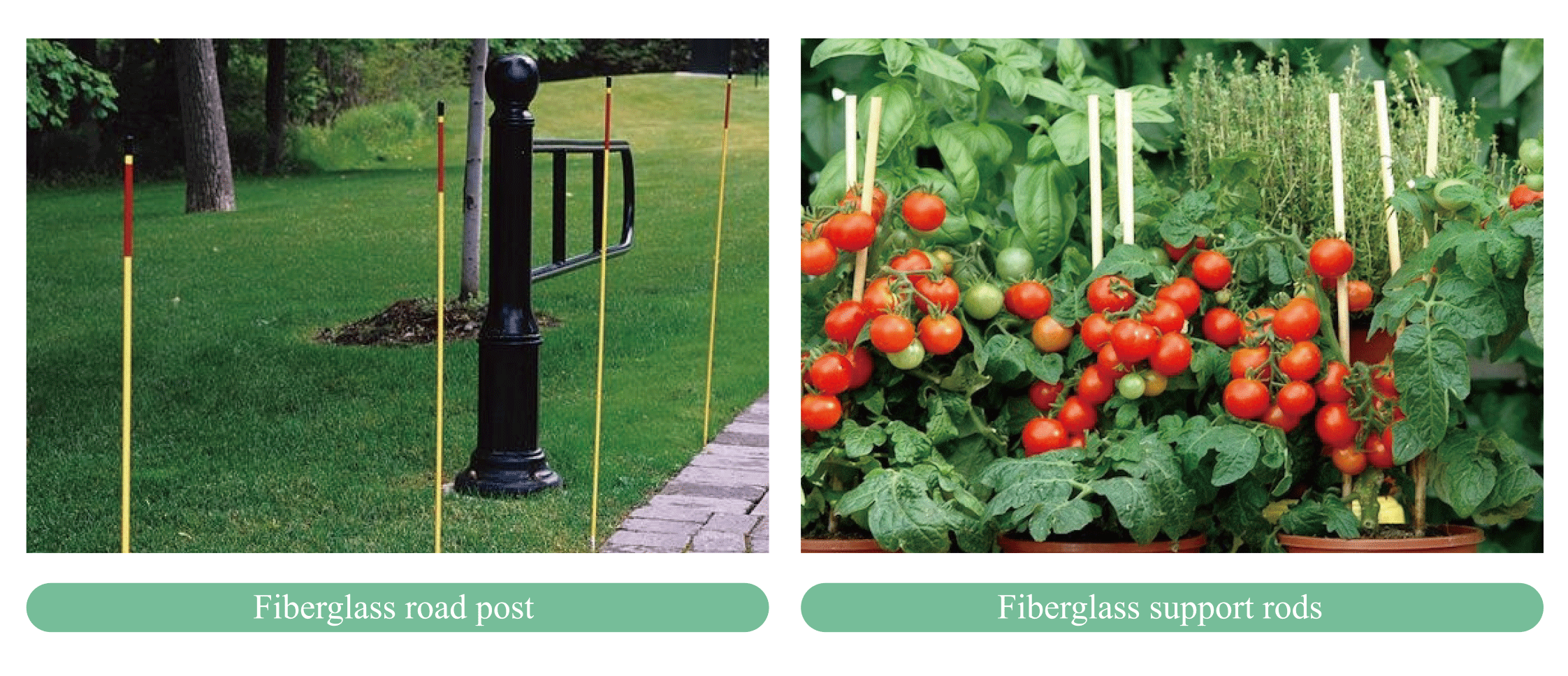

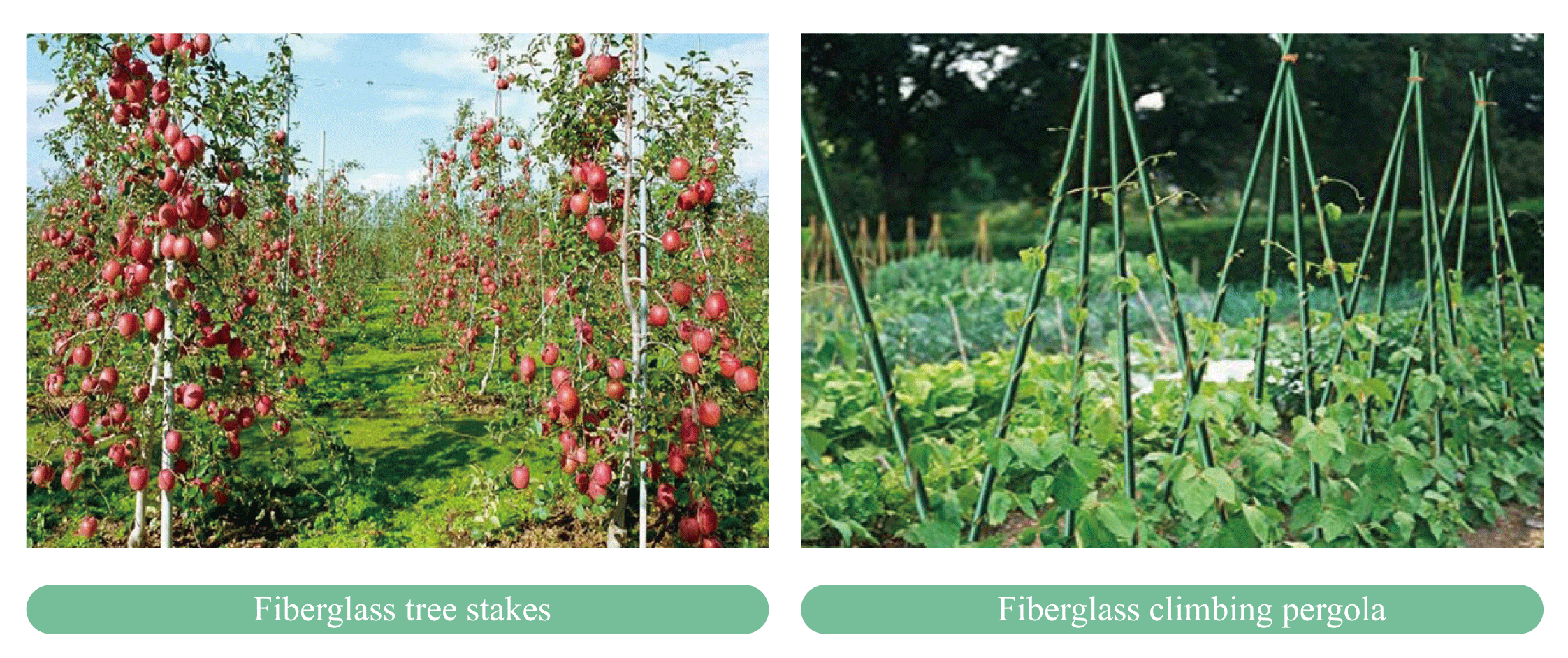

Landbouw: Glasvezelstaven hebben verschillende landbouwtoepassingen vanwege hun sterkte, duurzaamheid en weerstand tegen corrosie en strenge milieuomstandigheden. Ze worden vaak gebruikt in de volgende functies binnen de landbouwsector: Planten- en gewassteunen, veehegtrekken, irrigatiesystemen, plaagbeheer, kasconstructies en boom- en rankopleiding.

Dit zijn slechts een paar voorbeelden van de diverse toepassingsgebieden van ronde glasvezelstaven. Hun veelzijdigheid en eigenschappen maken ze geschikt voor een breed scala aan industrieën en toepassingen.

TECHNISCH INDEX VAN GFRP STAVEN

| Type | Afmetingen(MM) | Gewicht (KG/M) |

| 1-RB8.0 | 8.0 | 0.10 |

| 2-RB8.5 | 8.5 | 0.11 |

| 3-RB9.5 | 9.5 | 0.14 |

| 4-RB13 | 12.7 | 0.26 |

| 5-RB25 | 25.4 | 1.00 |

| 6-RB32 | 31.8 | 1.51 |

| 7-RB35 | 35.0 | 1.83 |

| 8-RB38 | 38.0 | 2.15 |

| 9-RB42 | 42.0 | 2.63 |

| 10-RB50 | 50.0 | 3.73 |

VERPAKKING EN OPBERGING

De verpakking van glasvezelstaven kan variëren op basis van de specifieke eisen en afmetingen van de staaf.

Meestal worden glasvezelstaven in bundels of spulen verpakt en vervolgens beschermd met geschikte materialen zoals plasticfolie, shrinkfolie of karton.

Daarnaast kunnen bij grote hoeveelheden de staven op europallets gemonteerd en met riemen vastgemaakt worden om een veilige transport te garanderen.

Bij internationale verzendingen worden de staven ingepakt volgens de betreffende voorschriften en normen om een veilige en betrouwbare levering te waarborgen. We kunnen ook ijzeren kaders monteren voor versterking. Als u specifieke verpakkingseisen of zorgen heeft, aarzel dan niet om meer details te geven voor een aangepaste oplossing.

DE PRODUKTIE-STAPPIES VOOR GLASVEZELSTAVEN

Stap 1 bestaat uit het bepalen van de benodigde hoeveelheid glasvezel direct roving op basis van de staafmaat en het verhouding tussen resin en vezel.

Stap 2 Direct roving wordt gedrenkt in resin om een sterke binding te creëren.

Stap 3 Bestaat uit extruderen en verwijderen van overbodige resin om de optimale resininhoud te bereiken.

Stap 4 Het voorbereide glasvezelroving wordt geplaatst in voormodels, klaar voor het volgende vormproces.

Stap 5 De voorgevormde roving wordt thermisch gehard in vormmodellen om de resin te solidifiëren en een robuuste glasvezelstaaf te produceren.

Product Type

In onze fabriek zijn we goed in het maken van op maat gemaakte glasvezelstaven, glasvezelbuizen, glasvezelbewapening, glasvezelgaten en andere glasvezelprofielen die precies aan je behoeften voldoen. Ons team van ingenieurs en ontwerpers is gespecialiseerd in het creëren van glasvezelproducten in allerlei maten en vormen.

Copyright © Chongqing Dujiang Composites Co., Ltd. All Rights Reserved