Paano gumawa ng fiberglass rod?

Fiberglass Rod ay isang uri ng kompyutado na material na may glass fiber roving at mga produkto nito bilang pagsusulong na material at sintetikong resin bilang matrix material. Ang proseso ng produksyon ay kabilang sa pangunahing mga hakbang na ito:

1. Paghahanda ng mga hilaw na materyales:

Glass fiber roving: pumili ngkoponan ng glass fiber roving, tulad ng E glass fiber roving.

Resin: Karaniwang ginagamit ang unsaturated polyester resin, epoxy resin, atbp., bilang binder at curing agent.

Tulakang materials: tulad ng curing agent, accelerator, mold release agent, atbp.

2. Pre-molding ng roving:

Inilalagay ang mga glass fiber rovings sa mold ayon sa disenyo ng mga layer at direksyon upang bumuo ng preformed body ng inaasang anyo. Maaaring ilagay ito sa pamamagitan ng kamay o automatikong pamamagitan ng makina.

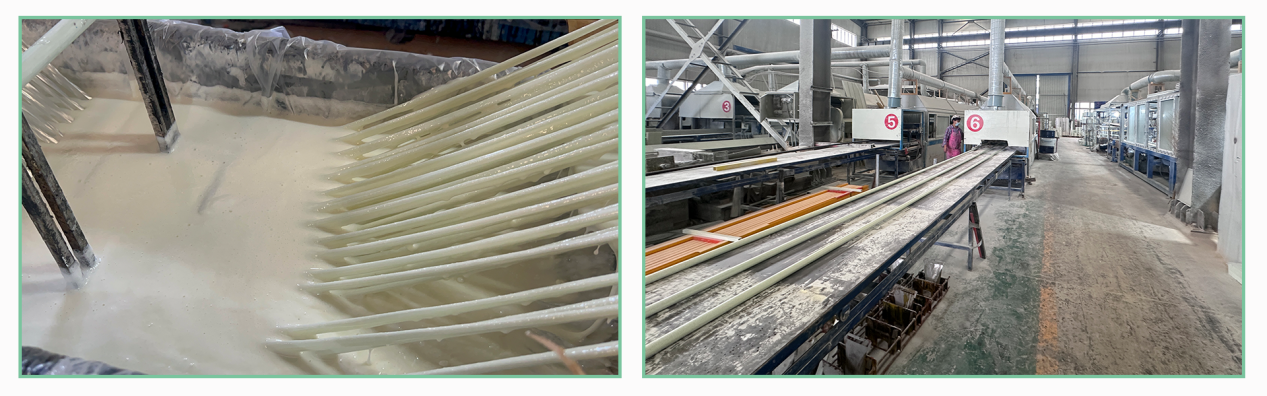

3. Impregnation:

Ang preformed fiberglass roving ay tinutunaw sa resin upang siguraduhin na ang mga yarn ay buong babagsak ng resin. Maaaring isagawa ang hakbang na ito sa pamamagitan ng iba't ibang paraan, tulad ng vacuum impregnation, pressure impregnation o transfer impregnation. Para sa frp rods , madalas gamitin ang proseso ng pultrusion molding, kung saan ginagamit ang isang espesyal na disenyo ng die upang patuloy na magproducce ng fiberglass rods ng inaasang laki sa ilalim ng traction.

4. Pagkukulay ng Resin:

Ang fiberglass roving na may resin ay kinukuha sa mold. Maaaring isagawa ang proseso ng pagkukulay sa temperatura ng silid o paikliin sa pamamagitan ng pagsasabog. Habang nagkuku-kulay, ang resin ay nagbabago mula sa likido hanggang sa solid na estado, kung saan nagbibigay lakas at anyo sa composite.

5. Pasadyang Pagsasanay:

Matapos ang pagkukulay, ang fiberglass rods ay naiuubos sa mga proseso ng pasadyang pagsasanay tulad ng paglalamig, paghuhupa, deburring, sanding at inspeksyon upang siguraduhin ang dimensional na katumpakan at kalidad ng ibabaw ng produkto.

6. Kontrol ng Kalidad:

Sa buong proseso ng produksyon, kailangang mabuti mong kontrolin ang kalidad ng mga materyales ng pangunahing sangkap, ang mga parameter ng proseso ng produksyon at ang pagganap ng huling produkto, upang siguradong bawat fiberglass Rod nakakamit ang mga pamantayan ng kalidad sa kadahilanang sukat, anyo, lakas at anyo.

Fiberglass rods ay madalas na ginagamit sa equipamento para sa palaruan, industriyal na kasangkapan, elektrikal at elektронiko, agrikultura at iba pang larangan dahil sa kanilang mahusay na katubusan at mataas na lakas, resistensya sa korosyon, mabuting insulasyon at iba pang karakteristikang. Sa panahon ng paggawa ng proseso, mahalaga na pansinin ang proteksyon sa kapaligiran at ligtas na produksyon upang bawasan ang epekto sa kapaligiran at mga operator.