The Ultimate Guide to Fiberglass Grating: Choosing the Right Type for Your Needs

When it comes to industrial flooring solutions, fiberglass grating has emerged as a popular choice due to its durability, lightweight nature, and resistance to corrosion. Whether you are looking for fiberglass floor grating for a commercial project or need to source from reliable FRP grating suppliers, understanding the different types of fiberglass grating available can help you make an informed decision. In this guide, we will explore the various types of fiberglass grating in our factory, including pultruded grating and molded fiberglass grating, and discuss their applications, benefits, and how to choose the right type for your needs.

What is Fiberglass Grating?

Fiberglass grating is a composite material made from a combination of fiberglass and resin. It is designed to provide a strong, lightweight, and corrosion-resistant flooring solution. Fiberglass grating is commonly used in various industries, including chemical processing, wastewater treatment, food and beverage, and marine applications. Its unique properties make it an ideal choice for environments where traditional materials like steel or wood may fail.

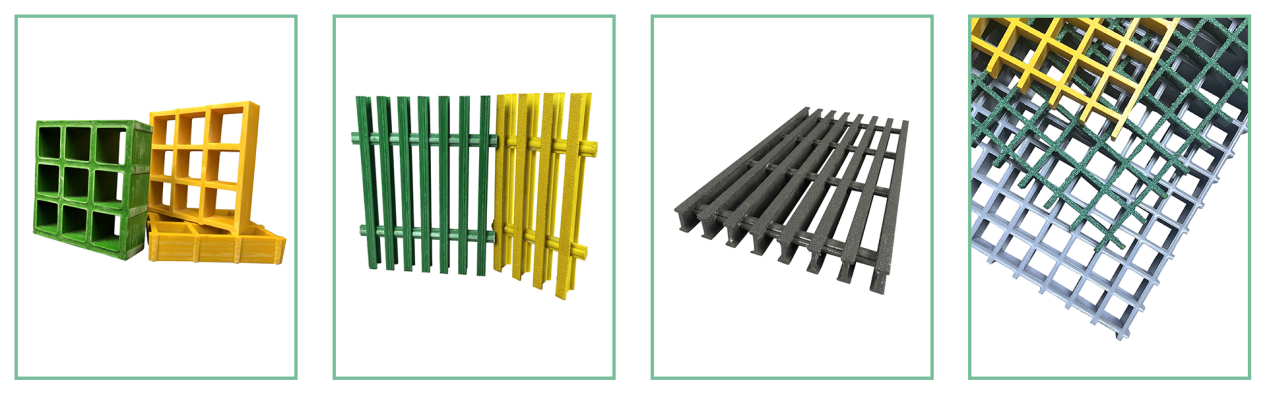

Types of Fiberglass Grating

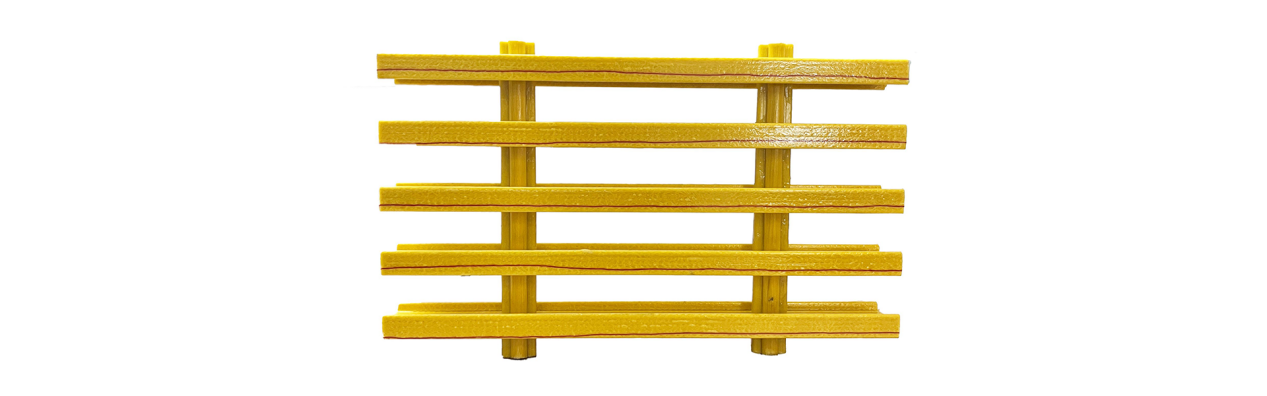

1. Pultruded Grating

Pultruded grating is manufactured through a process called pultrusion, where continuous strands of fiberglass are pulled through a resin bath and then shaped into a specific profile. This type of grating is known for its high strength-to-weight ratio and is often used in applications that require heavy loads and high impact resistance.

Benefits of Pultruded Grating:

High Load Capacity: Pultruded grating can support heavy loads, making it suitable for industrial applications.

Corrosion Resistance: It is resistant to a wide range of chemicals, making it ideal for environments with harsh conditions.

Low Maintenance: Pultruded grating requires minimal maintenance, reducing long-term costs.

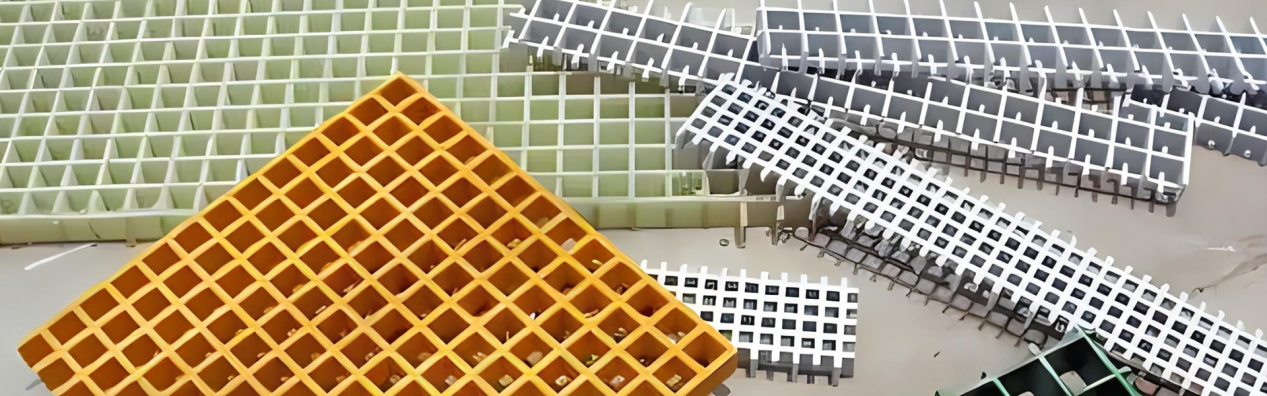

2. Molded Fiberglass Grating

Molded fiberglass grating is created by combining fiberglass strands with resin in a mold. This process allows for a variety of shapes and sizes, making it versatile for different applications. Molded grating is often used in areas where slip resistance is crucial, such as walkways and platforms.

Benefits of Molded Fiberglass Grating:

Slip Resistance: The surface of molded grating is designed to provide excellent traction, reducing the risk of slips and falls.

Customizable: Molded grating can be produced in various colors and sizes to meet specific project requirements.

Lightweight: It is easier to handle and install compared to traditional materials.

Applications of Fiberglass Grating

Fiberglass grating is used in a wide range of applications across various industries. Here are some common uses:

1. Chemical Processing Plants

In chemical processing plants, fiberglass grating is often used for walkways, platforms, and stair treads. Its resistance to corrosive chemicals makes it a safe choice for environments where spills may occur.

2. Wastewater Treatment Facilities

Fiberglass grating is commonly found in wastewater treatment facilities due to its ability to withstand harsh chemicals and moisture. It is used for catwalks, access platforms, and other areas where water exposure is frequent.

3. Food and Beverage Industry

In the food and beverage industry, hygiene is paramount. Fiberglass grating is non-porous and easy to clean, making it an excellent choice for processing areas, walkways, and storage facilities.

4. Marine Applications

Fiberglass grating is also widely used in marine applications, such as docks and piers. Its lightweight nature and resistance to saltwater corrosion make it ideal for these environments.

Choosing the Right FRP Grating Supplier

When selecting a supplier for fiberglass grating, it is essential to consider several factors to ensure you receive high-quality products that meet your specific needs.

1. Experience and Reputation

Look for suppliers with a proven track record in the industry. Check customer reviews and testimonials to gauge their reputation and reliability.

2. Product Range

A good supplier should offer a variety of fiberglass grating options, including pultruded and molded grating. This ensures you can find the right type for your application.

3. Customization Options

If your project requires specific dimensions or colors, choose a supplier that offers customization options. This flexibility can be crucial for meeting project specifications.

4. Technical Support

A knowledgeable supplier should provide technical support and guidance in selecting the right grating for your needs. They should be able to answer any questions you may have about installation, maintenance, and performance.

5. Warranty and Quality Assurance

Ensure that the supplier offers a warranty on their products. A solid warranty indicates confidence in the quality of their fiberglass grating.

We have all the above conditions, welcome to order our fiberglass grating.

Installation and Maintenance of Fiberglass Grating

Installation

Installing fiberglass grating is relatively straightforward, but it is essential to follow the manufacturer’s guidelines for best results. Here are some general steps to consider:

Preparation: Ensure the surface where the grating will be installed is clean and free of debris.

Cutting: If necessary, cut the grating to fit the desired area using appropriate tools.

Support Structure: Install a support structure that can adequately hold the weight of the grating and any loads it will bear.

Securing: Secure the grating in place using the recommended fasteners or clips.

Maintenance

One of the significant advantages of fiberglass grating is its low maintenance requirements. However, regular inspections are still essential to ensure its longevity. Here are some maintenance tips:

Cleaning: Regularly clean the grating surface to remove dirt, debris, and spills. Use a mild detergent and water for cleaning.

Inspection: Periodically inspect the grating for any signs of wear or damage. Address any issues promptly to prevent further deterioration.

Reinforcement: If the grating is subjected to heavy loads, consider reinforcing it as needed to maintain its structural integrity.

Conclusion

Fiberglass grating is a versatile and durable flooring solution suitable for various industrial applications. Understanding the differences between pultruded and molded fiberglass grating can help you choose the right type for your specific needs. By selecting a reputable FRP grating supplier and following proper installation and maintenance practices, you can ensure that your fiberglass grating will provide long-lasting performance and safety in your facility. Whether you are in the chemical processing, wastewater treatment, food and beverage, or marine industry, fiberglass grating is an excellent choice for your flooring needs. Chongqing Dujiang is worth your choice.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: [email protected]

Website: www.cqdjfrp.com