The Manufacturing Process of Fiberglass Solid Rods: What You Need to Know

The process of manufacturing solid fiberglass rods involves several steps that combine the properties of glass fibers and their products with synthetic resins. The main steps and characteristics of the process are described below:

1. Material composition

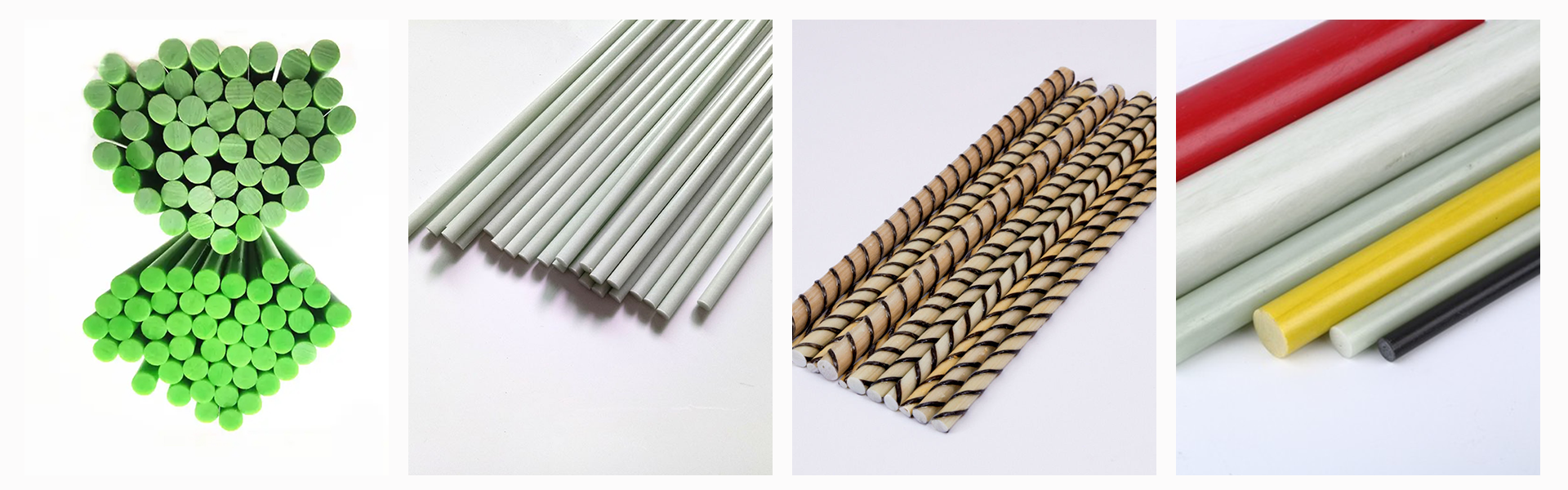

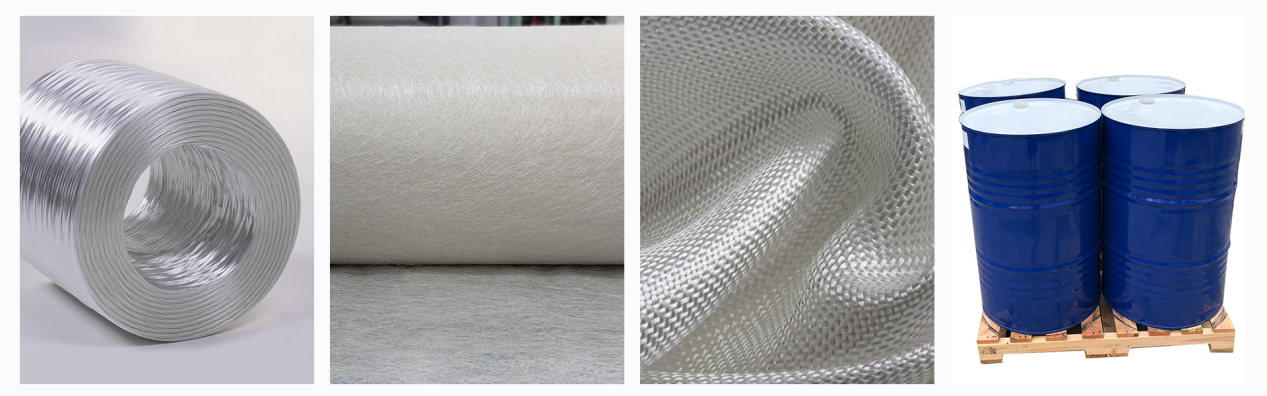

Fiberglass rods are composite materials made of glass fibers and their products (such as fiberglass woven roving, fiberglass tapes, fiberglass mats, fiberglass roving, etc.) as reinforcing materials, and synthetic resins as matrix materials.

2. Production process

The production process of fiberglass rod mainly includes the following steps:

(1)Addition of raw materials: Mixing mineral raw materials such as chlorite, kaolin, limestone, quartz sand and so on according to a certain ratio.

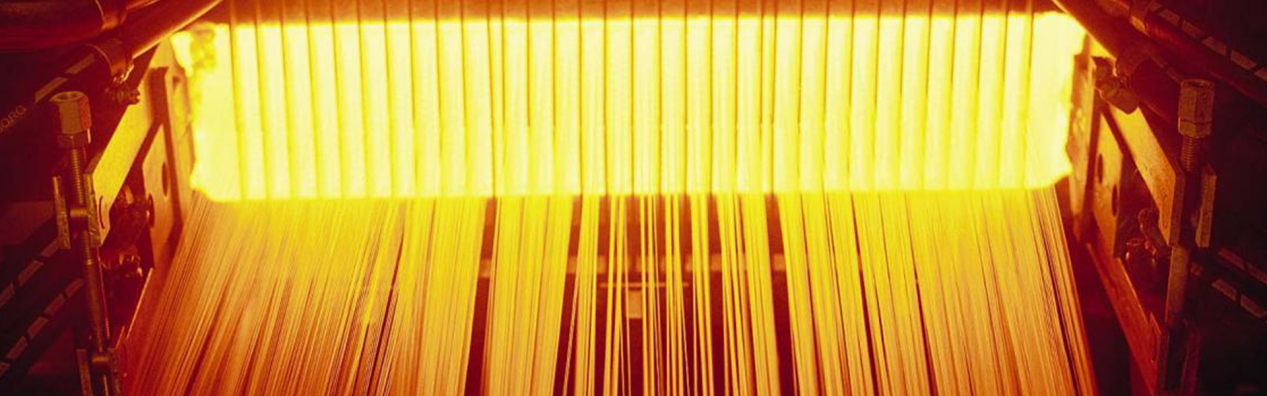

(2)Pool kiln melting: melting these mixed raw materials at high temperatures to form molten glass.

Drawing: The molten glass is processed and pulled to form very fine fibrous or filamentary glass materials.

(3)Impregnant Coating: Coating the surface of glass fibers with a special surface treatment agent to improve their properties.

(4)Drying and Annealing: Drying of the coated glass fibers.

(5)Production of products

Forming: After drying, the fiberglass can be processed into different products, such as fiberglass rod, as needed. This usually involves combining glass fibers with synthetic resins, molding and curing through a mold to form solid rods of a certain shape and size.

(6)Post-treatment

Post-processing: The formed fiberglass rods may require further post-processing such as cutting, grinding and surface treatment to meet specific application requirements.

This process embodies the entire transformation of fiberglass rod production from raw material preparation to the final product, and each step needs to be precisely controlled to ensure the quality and performance of the end product. Fiberglass rods are widely used in a number of applications due to their light weight and high strength, corrosion resistance and good electrical and thermal properties.

3. Features and applications

Fiberglass rods have the characteristics of light weight and high strength, corrosion resistance and good electrical and thermal properties. They are widely used in aviation, railroad, construction, furniture and other fields.

4. Manufacture of large-diameter composite solid bars

For the fabrication of large diameter composite solid rods, continuous pultrusion molding method is used. This includes the following steps:

Formulating multiple sets of pultrusion molding dies to accommodate the production of fiberglass rods of different diameters.

Preparation of inner core rods: long fibers of reinforcing fibers impregnated with resin glue are cured into inner core rods by means of pultrusion molding dies.

The inner core bar is polished and used as a core material, wrapped around the reinforcing long fibers impregnated with resin glue, and then formed and cured through the next set of pultrusion molding dies, gradually increasing the diameter.

The process is repeated until the target diameter is reached.

In summary, the manufacturing process of solid fiberglass rods is a complex process involving a variety of materials and processing steps designed to produce composites with specific properties.