The Future of Fiberglass Tubes: Latest Technological Breakthroughs

Fiberglass tubes have long been a cornerstone in industries ranging from construction to aerospace, thanks to their lightweight, durable, and corrosion-resistant properties. However, as technology advances, so does the potential of fiberglass tubes. In this blog, we’ll explore the latest technological breakthroughs shaping the future of fiberglass tubes and how these innovations are transforming industries.

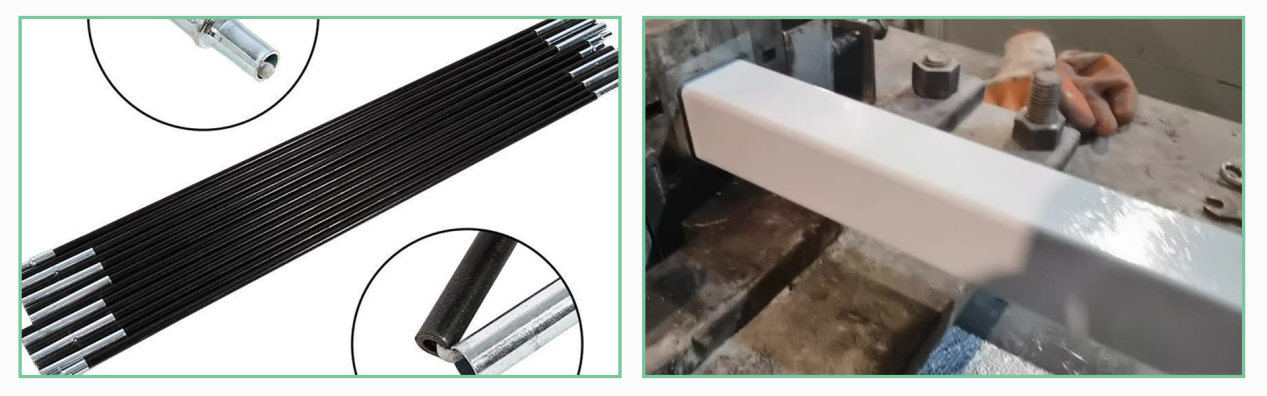

1. Introduction to Fiberglass Tubes

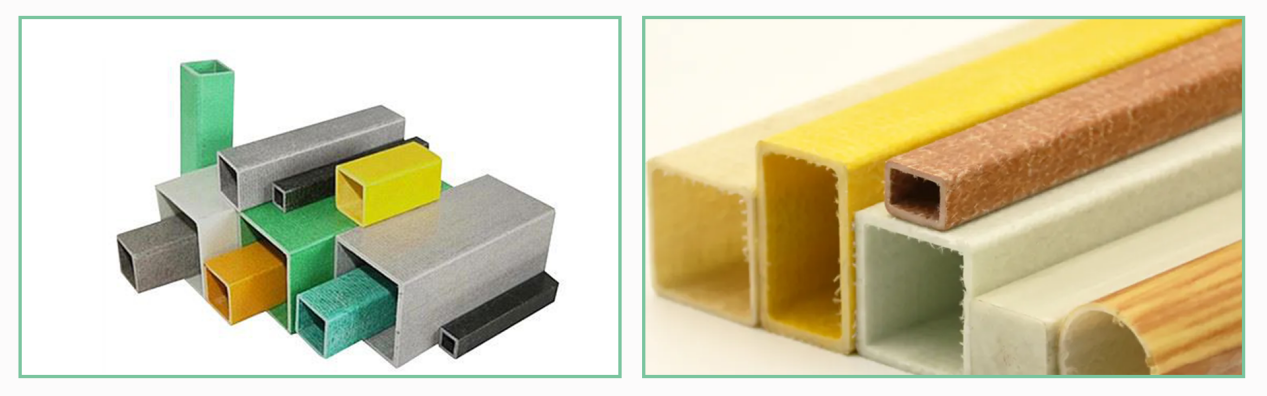

Fiberglass tubes, made from reinforced plastic and glass fibers, are known for their high strength-to-weight ratio and versatility. They are widely used in applications such as:

- Construction: Structural support and reinforcement.

- Aerospace: Lightweight components for aircraft.

- Renewable Energy: Wind turbine blades and solar panel frames.

- Automotive: Lightweight parts to improve fuel efficiency.

As demand for sustainable and high-performance materials grows, fiberglass tubes are at the forefront of innovation.

2. Latest Technological Breakthroughs in Fiberglass Tubes

2.1. Advanced Composite Materials

Recent developments in composite materials have led to fiberglass tubes with enhanced properties:

-Higher Strength: New resin formulations and fiber alignments increase load-bearing capacity.

-Improved Durability: Better resistance to UV radiation, chemicals, and extreme temperatures.

-Lightweight Design: Innovations in material science have made fiberglass tubes even lighter without compromising strength.

2.2. Smart Fiberglass Tubes

The integration of IoT (Internet of Things) technology is revolutionizing fiberglass tubes:

- Embedded Sensors: Sensors embedded within the tubes can monitor stress, temperature, and structural integrity in real-time.

- Predictive Maintenance: Data collected from these sensors enables predictive maintenance, reducing downtime and costs.

2.3. 3D Printing and Customization

3D printing technology is opening new possibilities for fiberglass tube manufacturing:

- Complex Geometries: 3D printing allows for the creation of intricate designs that were previously impossible.

- On-Demand Production: Customized fiberglass tubes can be produced quickly and cost-effectively.

2.4. Sustainable Manufacturing

As sustainability becomes a priority, the fiberglass tube industry is adopting eco-friendly practices:

- Recyclable Materials: New manufacturing processes use recyclable resins and fibers.

-Energy-Efficient Production: Innovations in production technology reduce energy consumption and carbon emissions.

3. Applications of Advanced Fiberglass Tubes

3.1. Renewable Energy

In the renewable energy sector, fiberglass tubes are critical for:

- Wind Turbine Blades: Lightweight and durable tubes improve turbine efficiency.

- Solar Panel Frames: Corrosion-resistant properties make them ideal for outdoor use.

3.2. Aerospace and Automotive

The aerospace and automotive industries benefit from:

- Weight Reduction: Lightweight fiberglass tubes enhance fuel efficiency and performance.

- High Strength: Advanced composites ensure safety and durability in high-stress environments.

3.3. Infrastructure and Construction

In construction, fiberglass tubes are used for:

- Structural Reinforcement: High-strength tubes provide stability in bridges and buildings.

- Utility Poles: Corrosion-resistant properties make them ideal for outdoor infrastructure.

4. The Future of Fiberglass Tubes: What's Next?

The future of fiberglass tubes looks promising, with several trends on the horizon:

- Nanotechnology: Incorporating nanomaterials could further enhance strength and durability.

- Biodegradable Composites: Research is underway to develop biodegradable fiberglass tubes for eco-friendly applications.

- AI-Driven Design: Artificial intelligence could optimize tube designs for specific use cases, improving performance and reducing waste.

5. Why Choose Fiberglass Tubes?

Fiberglass tubes offer numerous advantages over traditional materials like steel and aluminum:

- Lightweight: Easier to transport and install.

- Corrosion-Resistant: Ideal for harsh environments.

- Cost-Effective: Lower maintenance and longer lifespan.

6. Conclusion

The development of fiberglass tubes is immeasurable, and his series of technological breakthroughs have improved the performance, sustainability and versatility of fiberglass tubes. From smart tubes with built-in sensors to environmentally friendly manufacturing processes, these innovations are changing industries and creating a solid foundation for the development of new applications.

Whether you are in construction, agriculture, aerospace or renewable energy, fiberglass tube is a material worth exploring.