When humans think about constructing, say, homes, bridges, or roads, a mental image of immovable concrete blocks, solid bricks, and thick metallic beams usually arises. These materials are dense and very reliable, which is why they have been used for so long. On the downside, they tend to be quite large and difficult to move and assemble. As a result, it can increase both the time and money required for a construction project.

Today, engineers and builders seek alternative materials that can perform the work but are effortless to use compared to the first ones. Fiberglass rebar is one new material getting a lot of attention. The type of rebar is glass-fiber-reinforced plastic (GFRP) bar composed of tough but light glass fibers. Fiberglass rebar is lightweight, durable, and simple to install. This makes it an excellent choice for many kinds of construction projects. We are going to look at some of the benefits of fiberglass rebar for buildings.

Why is Fiberglass Rebar So Strong?

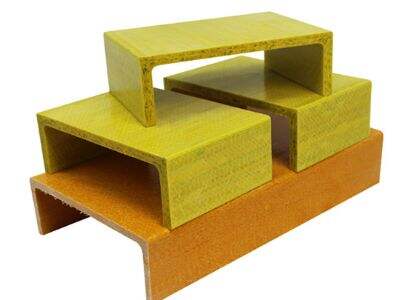

Concrete is a material that will crack and break if not taken care of or if it starts to age. Rebars are used by builders to make concrete Fiberglass Rod stronger. Those rebars are fixed in the concrete to enhance strength property. But there is a major drawback with Fiberglass Tube regular iron rebars: they can corrode when they come into contact with water. Rusting expands most metals, including GRP Grating iron, which will crack the concrete and cause damage.

You may have also noticed that fiberglass rebar never rusts. This means it can survive for much longer than typical iron rebars. It is as durable as steel rebar and does not swell in the wet or heat. This unique feature helps prevent concrete from cracking and results in safer and more durable buildings and structures.